How to Clean a Manitowoc Ice Machine: Best Practices for Hygienic Ice

Ice may seem like a simple beverage addition, but in commercial environments, it is considered food, making sanitation essential. Understanding how to clean a Manitowoc ice machine helps prevent contamination, maintain performance, and deliver safe, high-quality ice. Over time, scale, mineral deposits, mold, and bacteria can accumulate without regular Manitowoc ice machine cleaning, affecting taste, odor, and efficiency. Consistent care also protects key Manitowoc ice machine parts, reducing costly repairs. This guide outlines best practices, safety precautions, cleaning steps, and sanitization methods to keep your machine operating reliably.

Why Regular Cleaning of a Manitowoc Ice Machine Is Essential

Routine cleaning is not just about appearance—it directly impacts operational reliability and food safety.

1. Protects Ice Quality: When scale and biofilm accumulate, ice may appear cloudy, develop unusual flavors, or carry unpleasant odors. Customers notice these changes immediately, especially in food service environments.

2. Prevents Harmful Bacterial Growth: Ice machines operate in damp, dark conditions—ideal for microorganisms. Scheduled cleaning with a Manitowoc ice machine cleaner and sanitizer eliminates pathogens before they become a health risk.

3. Maintains Energy Efficiency: Scale buildup forces the machine to work harder during freeze cycles. Clean internal surfaces promote efficient heat transfer, lowering energy consumption and reducing operational costs.

4. Extends Equipment Lifespan: Mineral deposits can damage evaporators, pumps, and water lines. Protecting ice machine parts minimizes breakdowns and helps maintain consistent production.

5. Supports Compliance With Health Codes: Most local health authorities require documented cleaning schedules for commercial ice machines. Consistent maintenance helps avoid violations, fines, or temporary shutdowns.

6. Reduces Unexpected Downtime: Neglect often leads to clogged water systems or sensor malfunctions. Preventive cleaning keeps the machine dependable during peak business hours.

Simply put, Manitowoc ice machine cleaning is a proactive investment in both food safety and operational continuity.

Looking for a reliable supplier of commercial kitchen equipment parts in Canada? Shop now at PartsFe CA and simplify equipment maintenance with high-quality, commercial kitchen & restaurant equipment parts for cooking, refrigeration, ice machines, and beverage equipment. Our extensive inventory helps reduce downtime and keep your operations running efficiently. With competitive pricing, fast shipping across Canada, and dependable customer support, we are your reliable partner, always here to help keep your equipment running smoothly and at its best.

Tools, Solutions, and Safety Precautions Before You Start

Preparation ensures the cleaning process is efficient, safe, and compliant with food-service hygiene standards. Taking a few minutes to organize the right tools and review safety procedures can prevent equipment damage, reduce downtime, and help ensure your Manitowoc ice machine cleaning is thorough from start to finish.

Essential Cleaning Supplies

Before beginning how to clean a Manitowoc ice machine, gather the following:

-

Approved Manitowoc ice machine cleaner (nickel-safe if required)

-

Manufacturer-approved sanitizer

-

Soft nylon brush

-

Non-abrasive cloth or sponge

-

Protective gloves

-

Safety goggles

-

Bucket for draining water

-

Spray bottle

-

Screwdriver (if panels require removal)

Always avoid harsh chemicals or abrasive tools that could damage sensitive Manitowoc ice machine parts.

Choose the Right Cleaner

Using a cleaner specifically formulated for Manitowoc equipment is critical for maintaining long-term reliability. Generic descalers may appear effective but can degrade coatings or shorten the lifespan of internal components. A professional-grade Manitowoc ice machine cleaner and sanitizer is engineered to:

-

Break down calcium and lime deposits

-

Restore efficient heat transfer

-

Improve freeze consistency

-

Prevent premature wear on pumps and valves

Operators frequently ask, “How much Manitowoc ice machine cleaner to use?” While the exact amount varies by model, most machines require approximately 16 ounces (473 ml) per cleaning cycle. Underdosing may leave residue behind, while overdosing can require additional rinse cycles and increase chemical exposure.

For best results:

-

Always follow the manufacturer’s dilution ratios.

-

Measure carefully instead of estimating.

-

Use a fresh solution for every cleaning cycle.

When in doubt, consult your equipment manual to confirm the correct quantity and compatibility requirements.

Safety First

Because ice machines combine water, electricity, and chemical agents, safety must remain a top priority.

|

Safety Step |

Action |

Benefit |

|

Disconnect power |

Follow manual instructions |

Prevents electrical hazards |

|

Shut off the water supply |

If removing components |

Reduces flooding risk |

|

Never mix chemicals |

Use only approved products |

Avoids toxic reactions |

|

Ensure ventilation |

Maintain airflow |

Limits inhalation exposure |

|

Label the machine |

Mark as “Under Maintenance.” |

Prevents accidental use |

|

Train staff |

Review handling procedures |

Promotes consistent safety |

These measures protect both technicians and equipment during the cleaning of the ice machine.

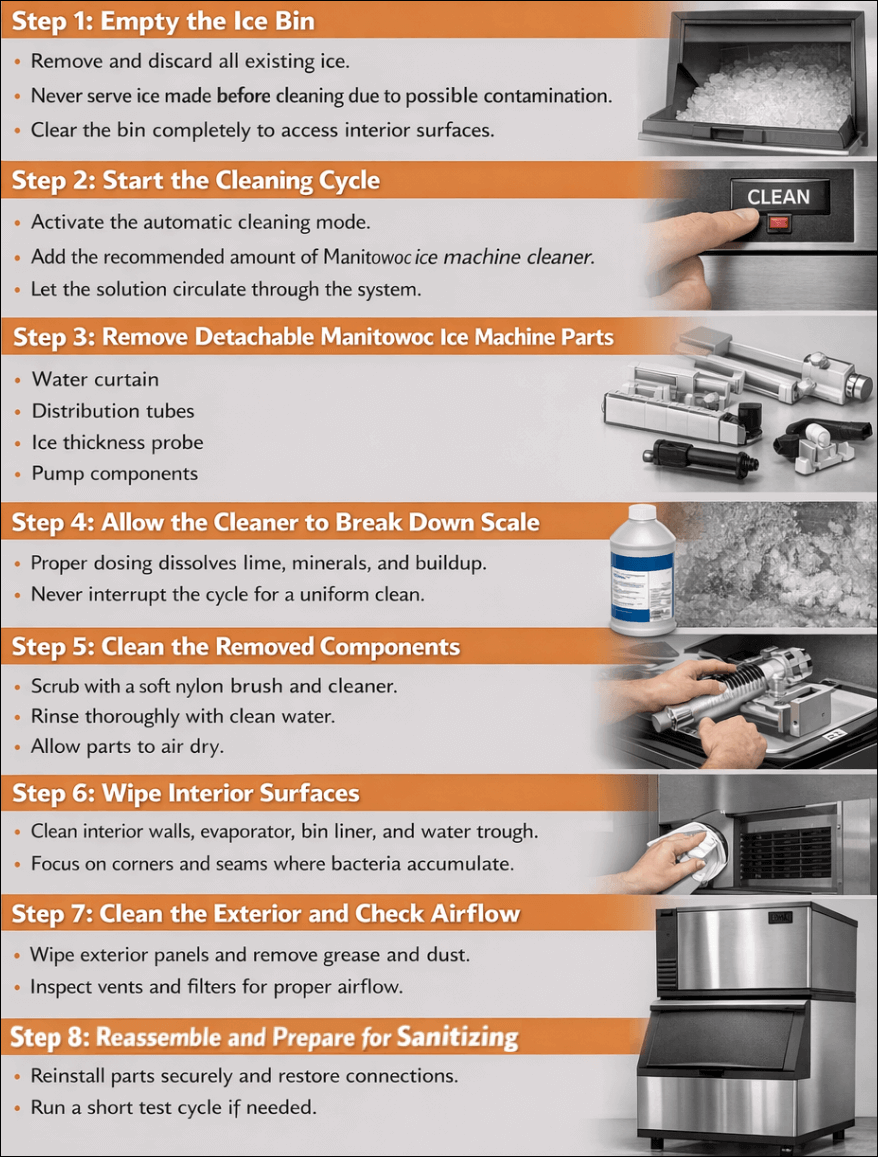

How to Clean a Manitowoc Ice Machine Step-by-Step

Understanding how to clean a Manitowoc ice machine correctly prevents accidental damage and ensures thorough results.

|

Disclaimer: This infographic provides a general overview of Manitowoc ice machine cleaning practices. Always refer to your equipment’s official manufacturer's manual for model-specific instructions and safety requirements before performing maintenance. |

Check out 5 signs you should clean or replace your ice machine, which highlights key warning indicators, maintenance insights, and guidance to help you maintain ice quality and equipment efficiency.

How to Sanitize a Manitowoc Ice Machine for Food Safety

Cleaning removes scale and debris; sanitizing destroys microorganisms. Both steps are essential.

Prepare the Sanitizing Solution: Use a manufacturer-approved sanitizer or the sanitizing portion of a Manitowoc ice machine cleaner and sanitizer system. Follow dilution guidelines precisely.

Run the Sanitizing Cycle: Many machines allow sanitizing immediately after cleaning. Add the solution to the trough and activate the cycle. This step disinfects water lines, pumps, and evaporator surfaces.

Sanitize the Ice Bin: Never overlook storage areas.

-

Spray sanitizer across interior walls.

-

Allow proper contact time.

-

Let surfaces air dry—do not rinse unless instructions require it.

Replace the Water Filter: A fresh filter improves water clarity and reduces mineral accumulation between cleanings.

Discard the First Batch of Ice: Once the unit resumes production, throw away the first harvest to ensure no sanitizer residue remains. When performed correctly, sanitizing guarantees hygienic ice suitable for consumption.

When to Call a Professional

While routine sanitizing can be handled in-house, certain situations require expert service to prevent long-term damage.

Consider calling a qualified technician if:

-

Scale buildup persists even after cleaning and sanitizing.

-

The machine produces cloudy, soft, or foul-smelling ice.

-

You notice leaks, unusual noises, or inconsistent production.

-

Internal ice machine parts, such as pumps or valves, show signs of wear.

-

The unit displays error codes or fails to complete cleaning cycles.

Professional maintenance ensures deeper inspection, protects warranty coverage, and helps identify small issues before they become costly repairs.

Explore how to troubleshoot common issues with Manitowoc ice machines, which covers frequent problems, diagnostic techniques, practical repair steps, and preventive maintenance tips to ensure consistent ice production and reliable operation.

Summary: Keeping Your Manitowoc Ice Machine Clean for High-Quality Ice

Maintaining a clean ice machine is essential for producing safe, clear ice and supporting reliable equipment performance. Understanding how to clean a Manitowoc ice machine and committing to a consistent maintenance schedule helps protect customers, optimize efficiency, and extend the lifespan of critical Manitowoc ice machine parts. By following recommended cleaning procedures, using approved chemicals, and routinely inspecting internal components, operations can reduce unexpected breakdowns while ensuring compliance with food safety standards.

Key Takeaways:

-

Consistent Manitowoc ice machine cleaning supports hygienic ice production and dependable machine performance.

-

Using approved Manitowoc ice machine cleaner products helps prevent scale buildup while protecting internal components.

-

Sanitizing after every deep clean eliminates microorganisms and strengthens food safety practices.

-

Routine inspection of essential ice machine parts allows early detection of wear and prevents costly repairs.

-

Replacing water filters as recommended improves ice clarity, taste, and overall system efficiency.

-

Documenting maintenance helps meet regulatory requirements and supports long-term operational reliability.

-

A proactive cleaning strategy minimizes downtime, lowers emergency repair costs, and ensures your machine continues delivering high-quality ice.

FAQs

How much Manitowoc ice machine cleaner to use?

The amount varies by model, but most machines require roughly 16 ounces of cleaner per cycle. Always consult the manufacturer’s guidelines to avoid under- or overdosing, which can affect cleaning performance or damage components.

What is the recommended cleaning frequency for a Manitowoc ice machine?

A general recommendation is every six months, though high-volume or hard-water environments may require cleaning every three months. If you notice scale buildup, cloudy ice, or reduced production, schedule cleaning sooner.

Why is my Manitowoc ice machine stuck in the clean cycle, and how can I exit it?

Typically, switching the control back to “Ice” mode or pressing the power button ends the cleaning cycle once it finishes draining. If the machine remains in cleaning mode, consult the user manual for model-specific reset instructions.