Powering Your Kitchen: Different Motors Used In Commercial Restaurant Equipment

In the commercial kitchen, the reliable performance of restaurant equipment is crucial to ensuring seamless operations and exceptional culinary experiences. In the kitchen are a diverse array of motors, each designed to power specific functions and appliances. From refrigeration and ventilation to food preparation and cooking, the motors in commercial restaurant equipment play a pivotal role in delivering efficiency, precision, and durability. the dynamic world of motors used in commercial restaurant equipment. We will delve into the various types of motors, their applications, and the technological innovations driving the evolution of kitchen equipment.

What is a motor?

A motor is a device that converts electrical energy into mechanical energy. In commercial applications, such as restaurant equipment, electric motors are commonly used. These motors operate by generating torque, or rotational force, through the interaction of a magnetic field and a current-carrying conductor, often referred to as an armature. Typically, alternating current (AC) is used to power these motors, though direct current (DC) can also be utilized. AC motors are prevalent due to their versatility and efficiency, while DC motors are known for their higher operating speed and efficiency, albeit with lower starting torque.

In the realm of commercial restaurant equipment, motors are integral components in various appliances like ovens, ranges, stoves, dishwashers, ice machines, and griddles. Hoshizaki and Manitowoc are well-known producers of electric motors for such equipment, producing motors that are noted for their reliability and performance.

Motor types and applications

Electric motors come in various types, each suited for specific applications based on factors like operation, voltage, and function.

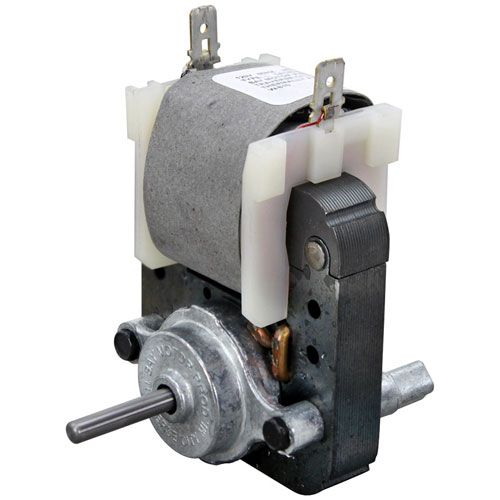

Evaporator fan motor

-

Function: Circulates air through evaporator coils to remove heat from moving air in refrigeration systems.

-

Location: Typically installed behind panels in freezer or refrigerator compartments.

-

Importance: Crucial for maintaining proper temperature in refrigeration appliances.

Condenser fan motor

-

Function: Moves air over condenser coils to release heat into the surrounding environment in appliances like refrigerators and air conditioners.

-

Structure: Consists of a rotor with blades rotating around a shaft and a stator with coils and permanent magnets.

-

Application: Widely used in various cooling appliances.

Fan blower motor

-

Function: Provides a constant flow of air for cooking and heating purposes in kitchen appliances.

-

Installation: Mounted on walls with ducts connected to cooking areas.

-

Usage: Essential for maintaining airflow and ventilation in commercial kitchens.

Pump motors

-

Function: Convert mechanical energy into hydraulic energy to move fluids in appliances like washing machines and dishwashers.

-

Operation: The kinetic energy of water or steam rotates a shaft connected to an external gearbox.

-

Application: Essential for fluid movement in various household and commercial appliances.

Hydraulic motors

-

Function: Convert rotary motion into linear motion using fluid pressure, commonly used in appliances like dishwashers and ovens.

-

Mechanism: Pistons driven by fluid pressure cause the rotational motion of a shaft connected to pulleys.

-

Purpose: Enables linear force generation for various applications in kitchen appliances.

AC motors

-

Function: Convert electrical energy from alternating current (AC) into mechanical rotational energy, widely used in appliances like conveyors, machine tools, HVAC systems, and pumps.

-

Advantages: Low initial power demand, controlled velocities, scalable operational speed, and adjustable torque limit.

-

Application: This versatile motor type is suitable for various industrial and commercial applications.

DC motors

-

Function: Convert electrical energy from direct current (DC) into mechanical motion, offering benefits like simple installation, broad speed control, high starting torque, and linear speed-torque curve.

-

Usage: Suitable for applications requiring precise speed control and high starting torque, such as conveyor belts, elevators, and hoists.

-

Limitation: Restricted usage in environments with flammable or hazardous gases due to potential sparking.

These various types of electric motors cater to a wide range of applications, providing efficient and reliable performance in commercial and household appliances.

What's the difference between an AC and a DC motor?

Here’s the difference between an AC and a DC motor:

|

Feature |

AC Motor (Alternating Current) |

DC Motor (Direct Current) |

|

Power Source |

Runs on standard wall outlet power (alternating current) |

Requires a converter or battery for direct current |

|

Usage in Kitchens |

Common in large appliances like refrigerators, ovens, mixers, and HVAC units |

Used in equipment needing precise speed control, like blenders or slicers |

|

Speed Control |

Less precise; needs extra equipment to vary speed |

Excellent speed control for tasks like cutting or blending |

|

Maintenance |

Low; ideal for equipment that runs for long hours |

Higher; brushes wear out over time |

|

Durability |

Durable and reliable for heavy-duty use |

More wear and tear, especially in high-use tools |

|

Cost |

Lower upfront cost; easier to replace or repair |

Typically more expensive; may need special parts |

|

Efficiency |

Best for continuous operation, like in walk-in coolers or exhaust fans |

Better for start-stop equipment, such as dough mixers or food processors |

|

Starting Torque |

Moderate; sufficient for most heavy kitchen appliances |

High; ideal for machines that need a strong start, like meat grinders |

How does a motor operate in commercial restaurant equipment?

Commercial restaurant equipment is significantly reliant on several types of motors to power vital tasks, ensuring the kitchen's effective operation and consistent client service. These motors are essential components of a variety of appliances, including refrigerators, fryers, ovens, griddles, grills, and ice makers.

|

Equipment |

Motor functions |

Purpose |

|

Oven |

Control convection fans, rotating rotisseries, and moving conveyor belts. |

Even heat distribution, uniform, and efficient cooking. |

|

Adjust cooking surface height for precise temperature control. |

Ensures even cooking by regulating distance from heat source. |

|

|

Ice machine |

Drive evaporator plate for ice production, and auger for ice dispensing. |

Produces and dispenses ice for beverages and food preservation. |

|

Fryer |

Agitate oil and move frying baskets in and out of the frying chamber. |

Ensures even frying, simplifies cooking and draining of oil. |

|

Dishwasher |

Pump water, rotate spray arms, and move racks. |

Circulates water for cleaning distributes water for thorough cleaning, and aids in loading and unloading dishes. |

|

Refrigerator |

Compress refrigerant gas, drive evaporator, and condenser fans. |

Maintains proper temperatures, and ensures consistent cooling. |

What function does a capacitor serve in a motor?

A capacitor in a motor serves critical functions essential to its operation. One primary function is providing starting torque in single-phase induction motors by creating an additional phase shift in the motor's winding, enabling it to overcome inertia and initiate motion efficiently. Additionally, capacitors are used to induce phase shifting in the motor, which is crucial for ensuring effective operation, particularly in single-phase motors. Furthermore, capacitors contribute to power factor correction, enhancing the motor's efficiency by optimizing the ratio of useful power to total power consumed. By improving power factor and efficiency, capacitors play a key role in enhancing motor performance, reducing energy consumption, and ensuring reliable operation across a wide range of industrial, commercial, and residential applications

Motor capacitor varieties

There are three types of motor capacitors: motor run, motor start, and power factor correction.

-

Motor run capacitors: During motor operation, motor run capacitors maintain a steady charge to optimize the motor's running performance. They remain active while the motor is running and contribute to its efficiency. These capacitors are crucial for applications requiring continuous motor operation, such as fans, blowers, and pumps.

-

Motor start capacitors: Motor start capacitors briefly hold an electrical charge during the motor starter, providing extra torque. They are intended to help with motor beginning and are disconnected from the circuit after the motor has reached its operational speed.

-

Start capacitors are widely employed in applications that demand a high starting torque, such as air conditioners, compressors, and conveyors.

-

Power factor correction capacitors: Power factor correction capacitors balance the working and supplied power of a motor, lowering energy consumption from strong inductive loads. They increase the overall efficiency of motor-driven systems by reducing reactive power consumption and optimizing the power factor. Conveyors, compressors, and saws all require these capacitors to operate properly.

In commercial kitchen appliances, various types of motors are utilized, each serving specific functions based on the appliance's requirements. Proper sizing and selection of motors are crucial for ensuring optimal performance, efficiency, and cost-effectiveness of the appliance. Some appliances may feature multiple types of motors, depending on their category and operational needs.

PartsFe offers a comprehensive selection of high-quality products from top-selling brands. From oven knobs to heating elements and ice machine water filters, PartsFe provides cost-effective solutions with reliable same-day shipping services.

FAQs

Can variable speed motors improve efficiency in commercial kitchen appliances?

Yes, variable speed motors can enhance efficiency by adjusting the motor speed to match the equipment's requirements, reducing energy consumption and operational costs.

Can motors be retrofitted or upgraded in existing commercial kitchen equipment?

Yes, motors can often be retrofitted or upgraded in existing commercial kitchen equipment to improve performance or replace outdated components.

What safety considerations should restaurant owners keep in mind regarding motor usage in kitchen appliances?

Restaurant owners should ensure proper ventilation to prevent motor overheating, follow maintenance schedules to avoid malfunctions, and regularly inspect wiring to mitigate fire risks.