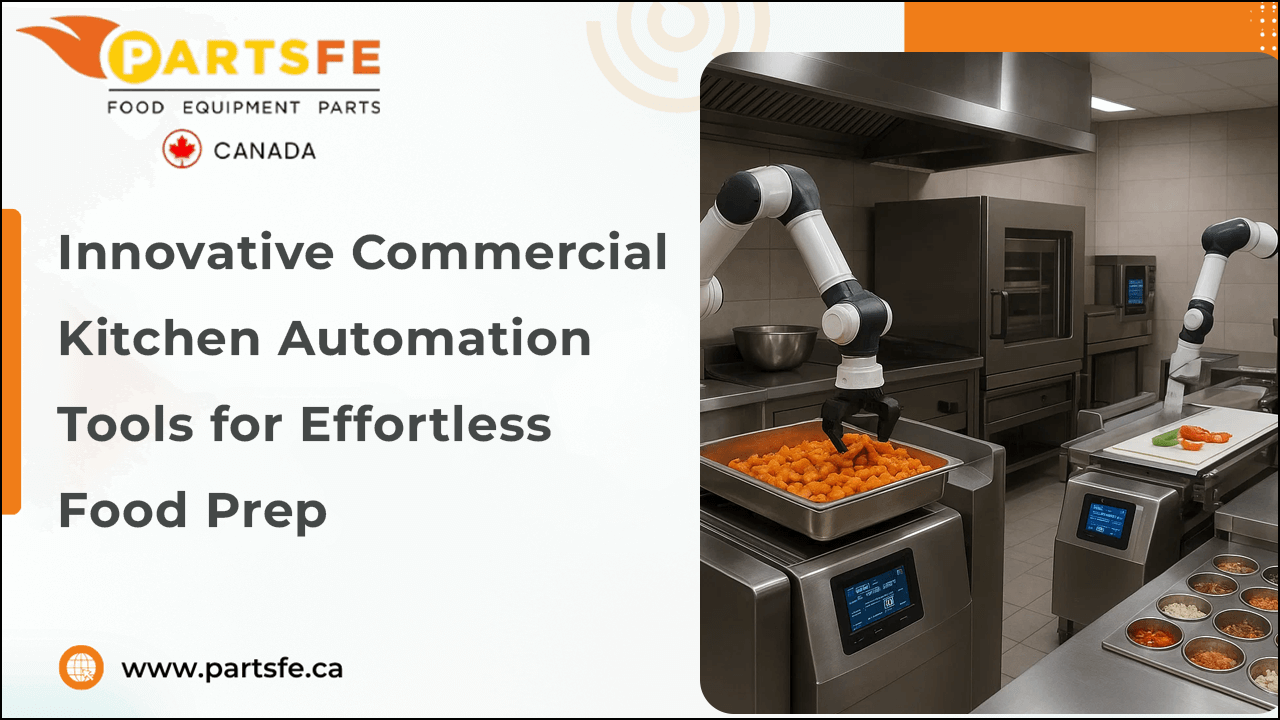

Innovative Commercial Kitchen Automation Tools for Effortless Food Prep

The commercial kitchen landscape is rapidly evolving. With rising demand for speed, consistency, and strict hygiene, foodservice operators are increasingly turning to automation. From busy restaurants to large-scale production kitchens, the need to streamline operations while maintaining quality has never been greater.

Commercial kitchen automation tools are revolutionizing food prep. These advanced technologies simplify complex tasks, reduce labor costs, and boost productivity. More than just machines, they enhance workflows, reduce errors, and ensure faster, more consistent results.

In this article, we’ll highlight the most impactful automation tools transforming the foodservice industry. Designed to deliver effortless efficiency, these innovations free up chefs and staff to focus on creativity, quality, and exceptional customer experiences rather than repetitive prep work.

| Table of Contents: Understanding the Role of Automation in Modern Commercial Kitchens Essential Cutting-Edge Commercial Kitchen Automation Tools Benefits of Implementing Automation in Commercial Kitchens How to Choose the Right Automation Tools for Your Commercial Kitchen Final Thoughts: Future Trends in Commercial Kitchen Automation |

Understanding the Role of Automation in Modern Commercial Kitchens

Automation has become essential in commercial kitchens, helping operators keep up with the fast pace of today’s foodservice environment. Beyond just saving time, automation enables kitchens to innovate, improve accuracy, and handle complex workflows with greater ease.

Key roles of automation in commercial kitchens include:

-

Optimizing Workflow Integration: Automated tools seamlessly connect various prep stations and ovens, reducing bottlenecks and improving coordination between kitchen teams.

-

Enhancing Data-Driven Decisions: Many automated systems collect valuable data on production times, ingredient usage, and equipment performance, allowing managers to make smarter operational choices.

-

Adapting to Menu Complexity: Automation supports diverse and customizable menus by precisely executing complicated recipes or assembly processes without human error.

-

Improving Employee Satisfaction: By automating tedious, repetitive tasks, staff can focus on creative, skilled work, increasing job satisfaction and reducing burnout.

-

Facilitating Regulatory Compliance: Automated documentation and traceability features help kitchens adhere to food safety regulations and quality standards effortlessly.

-

Enabling Remote Monitoring and Control: Smart automation systems allow managers to oversee kitchen operations in real-time from anywhere, improving responsiveness and reducing downtime.

In this way, automation isn’t just about speed, it’s a strategic tool that elevates the entire kitchen operation.

Read this article on restaurant equipment trends in the foodservice industry to explore how innovations like smart ovens, modular setups, and automation are reshaping kitchen operations and customer experiences.

Essential Cutting-Edge Commercial Kitchen Automation Tools

Cutting-edge automation tools are revolutionizing commercial kitchens by making food preparation faster, more accurate, and more efficient. These essential innovations help kitchens meet high standards while reducing workload and waste.

Miso Robotic’s Flippy 2.0

An AI-powered robotic cook that autonomously handles grilling, frying, and flipping tasks using advanced computer vision and machine learning.

Transforms Food Prep: Flippy 2.0 accelerates cooking processes while reducing human error and fatigue, allowing kitchens to maintain consistent speed and quality during busy service times.

Impact in Commercial Kitchens:

-

Improves Kitchen Safety: Automates hot and hazardous cooking tasks, reducing staff injuries.

-

Increases Order Throughput: Handles high-volume frying and grilling during peak hours.

-

Maintains Consistent Product Quality: Ensures every item meets brand standards without variation.

Spoonshot AI-Powered Flavor Prediction

An AI platform that analyzes vast flavor data to suggest innovative ingredient combinations and recipe ideas for chefs.

Transforms Food Prep: Spoonshot shortens the experimentation phase and enables chefs to confidently develop new recipes that appeal to customer tastes, speeding up the introduction of innovative menu items.

Impact in Commercial Kitchens:

-

Accelerates Menu Innovation: Enables chefs to create new dishes based on data-driven flavor insights.

-

Reduces Costly R&D Time: Streamlines recipe development to quickly respond to market trends.

-

Supports Customized Offerings: Tailors dishes to diverse customer preferences.

Zimplistic Rotimatic

A smart appliance that automates the entire process of making fresh flatbreads, including dough preparation, rolling, and cooking.

Transforms Food Prep: Rotimatic streamlines a time-consuming manual process, enabling kitchens to produce large quantities of fresh flatbreads with minimal labor and consistent quality.

Impact in Commercial Kitchens:

-

Boosts Production Capacity: Automates labor-intensive flatbread prep during busy service periods.

-

Ensures Consistent Product Quality: Standardizes dough preparation and cooking processes.

-

Frees Skilled Staff: Allows chefs to focus on complex menu items instead of basic breadmaking.

Picnic Automated Food Assembly System

A robotic system designed to assemble complex sandwiches, salads, and bowls with precision and speed.

Transforms Food Prep: Picnic revolutionizes the assembly line by automating intricate ingredient layering, reducing prep time and errors while increasing output.

Impact in Commercial Kitchens:

-

Increases Operational Efficiency: Automates complex sandwich and bowl assembly for faster prep.

-

Enhances Portion Control: Minimizes food waste and controls costs by precise ingredient dispensing.

-

Reduces Labor Dependency: Frees kitchen staff from repetitive assembly tasks.

Brava Smart Oven

A countertop smart oven using advanced light technology to cook food rapidly and evenly with pre-programmed recipes.

Transforms Food Prep: Brava drastically reduces cooking times for complex dishes, enabling kitchens to serve more customers faster without sacrificing quality.

Impact in Commercial Kitchens:

-

Cuts Cooking Time: Enables rapid food preparation during peak hours.

-

Delivers Consistent Cooking Results: Ensures dishes meet quality standards without constant supervision.

-

Lowers Energy Costs: Uses efficient light-based heating optimized for commercial use.

CleanRobotics’ TrashBot

An AI-powered smart waste bin that automatically sorts trash into compost, recycling, or landfill categories, improving kitchen sustainability.

Transforms Food Prep:

TrashBot streamlines waste disposal, keeping prep areas clean and compliant, allowing staff to focus on food production instead of sorting waste.

Impact in Commercial Kitchens:

-

Improves Waste Management: Automatically sorts kitchen waste to comply with sustainability regulations.

-

Reduces Labor Costs: Minimizes time spent on manual waste separation.

-

Supports Eco-Friendly Operations: Helps kitchens achieve green certifications and reduce environmental impact.

Karakuri Kitchen Robotics

Robotic meal assembly systems that precisely portion and pack ready-to-eat meals at high speeds.

Transforms Food Prep: Karakuri’s robots automate complex portioning and packaging, speeding up service and reducing food waste while ensuring hygiene.

Impact in Commercial Kitchens:

-

Enhances Meal Prep Speed: Rapidly assembles ready-to-eat meals to meet high demand.

-

Improves Accuracy and Hygiene: Consistently portions meals with minimal human contact.

-

Protects Staff Health: Reduces repetitive strain injuries by automating manual tasks.

Moley Robotics Kitchen Robot

A fully autonomous robotic kitchen capable of cooking a wide variety of dishes by mimicking a human chef’s movements with robotic arms.

Transforms Food Prep:

Moley Robotics brings full kitchen automation, dramatically reducing labor needs and delivering restaurant-quality dishes consistently.

Impact in Commercial Kitchens:

-

Automates Complex Cooking: Prepares a variety of dishes with minimal human intervention.

-

Increases Kitchen Productivity: Operates 24/7 to meet high-volume demand.

-

Ensures Recipe Consistency: Replicates chef-quality cooking precisely every time.

Cafe X Robotic Barista

A robotic coffee system automates everything from bean grinding to espresso extraction and milk frothing, serving barista-quality coffee rapidly.

Transforms Food Prep: Cafe X automates beverage preparation, freeing staff and speeding up drink service alongside kitchen operations.

Impact in Commercial Kitchens:

-

Speeds Beverage Service: Delivers coffee quickly to reduce customer wait times.

-

Maintains Drink Quality: Produces consistent barista-standard beverages.

-

Optimizes Kitchen Workflow: Integrates beverage prep seamlessly with food service operations.

Check out our article on transforming food service: the future of flake ice machines to find how advanced automation and energy-efficient technology are reshaping ice production in commercial kitchens.

Benefits of Implementing Automation in Commercial Kitchens

Automation in commercial kitchens brings a host of innovative advantages that extend beyond traditional efficiency gains, fostering a smarter, more resilient kitchen environment:

-

Predictive Maintenance: Automated systems can monitor their own condition and predict equipment failures before they happen, reducing unexpected downtime.

-

Customized Nutritional Adjustments: Automation tools can modify recipes on-the-fly to meet specific dietary requirements such as low-sodium, gluten-free, or keto diets.

-

Enhanced Staff Safety Through Ergonomics: Automation reduces the need for repetitive or awkward movements, lowering the risk of musculoskeletal injuries among kitchen workers.

-

Real-Time Allergy Alerts: Automated prep stations can flag potential cross-contact risks and alert staff, improving food allergy management.

-

Dynamic Portion Scaling: Automation allows kitchens to adjust portion sizes instantly based on demand, minimizing food waste during fluctuating service volumes.

-

Cross-Channel Consistency: Automated kitchen workflows ensure menu items are prepared identically whether for dine-in, takeout, or delivery, preserving brand reputation.

-

Integrated Sustainability Tracking: Automation can quantify water, energy, and waste metrics, helping kitchens transparently report their environmental impact.

-

Boosted Creativity: By offloading routine tasks, automation frees up chefs’ mental bandwidth to experiment and innovate with new dishes and presentation styles.

These forward-thinking benefits highlight how automation is not just a time saver but a transformative force in modern commercial kitchens.

How to Choose the Right Automation Tools for Your Commercial Kitchen

Choosing automation tools should depend on the type and scale of your kitchen. Here's how different commercial kitchen formats can benefit from specific automation solutions:

Quick-Service Restaurants (QSRs)

Speed and consistency are critical.

-

Patty Formers & Grills: Ensure perfectly shaped and evenly cooked burgers every time.

-

High-Speed Ovens: Reduce wait times with rapid cooking for pizzas, sandwiches, and more.

-

Sauce & Condiment Dispensers: Minimize waste and maintain flavor consistency across orders.

-

Touchless Beverage Dispensers: Speed up drink service while improving hygiene.

Cloud/Delivery-Only Kitchens

Efficiency and compactness are key.

-

Multi-Functional Prep Stations: Save space and time with tools that chop, blend, and mix.

-

Automated Fryers/Rice Cookers: Program fryer cycles for perfect results without constant monitoring.

-

Smart Inventory Systems: Track stock levels in real time across multiple virtual brands.

-

Integrated POS & Order Screens: Manage high-volume delivery orders smoothly.

Large-Scale Catering & Commercial Kitchens

High volume, low error tolerance.

-

Bulk Prep Equipment: Use heavy-duty slicers, dicers, and mixers to handle large quantities.

-

Robotic Packing Systems: Automate plating and portioning for speed and accuracy.

-

Blast Chillers & Combi Ovens: Preserve food quality with precise temperature control.

-

High-Capacity Dishwashers: Ensure quick turnaround of cookware and utensils.

Bakeries and Cafés

Precision and repeatability matter.

-

Dough Sheeters & Depositors: Shape and portion pastries consistently with minimal effort.

-

Automated Coffee Machines: Deliver barista-level beverages with programmable recipes.

-

Programmable Ovens: Bake goods to perfection with preset cycles and timers.

-

Portion Control Scales: Ensure ingredient accuracy and reduce waste.

Final Thoughts: Future Trends in Commercial Kitchen Automation

As commercial kitchen technology continues to advance, automation is shifting from a competitive advantage to an operational necessity. Emerging trends like AI-powered cooking, IoT-enabled appliances, and real-time data analytics are set to redefine how kitchens operate—making them smarter, faster, and more sustainable. With ongoing challenges such as labor shortages and rising costs, automation tools will be essential for improving efficiency, reducing errors, and maintaining consistency at scale. Kitchens that invest in the right automation solutions today will be better equipped to adapt, grow, and deliver exceptional food experiences in the future. Embracing innovation now means staying ahead of the curve in an ever-evolving industry.

Looking to upgrade your kitchen with top-notch parts? PartsFeCA offers a vast selection of essential commercial kitchen components to keep your equipment performing at its best. Find parts like thermostats, fryer baskets, and conveyor oven belts from leading brands such as Pitco, Vulcan, and Lincoln, all available in one convenient place.

FAQs

What are the best automation tools for a commercial kitchen?

Some of the best tools include automated slicers, robotic food prep arms, programmable ovens, smart mixers, and conveyor ovens. The right choice depends on your kitchen’s specific needs and volume.

How can automation tools improve food preparation in commercial kitchens?

Automation tools increase speed, ensure consistent portioning and quality, reduce human error, and free up staff to focus on creative tasks, ultimately boosting overall kitchen efficiency.

Do commercial kitchens need special training to use automation tools?

Most modern automation equipment is designed to be user-friendly, but some training is recommended to maximize efficiency and ensure safe operation.