How Flake Ice Machines Are Transforming Modern Food Service Industry in 2026

The food service industry in 2026 prioritizes speed, safety, sustainability, and consistency, making equipment selection a strategic decision. As operators face higher customer expectations and stricter regulations, the flake ice machine has become a core solution for modern food handling, storage, and presentation.

Offering superior cooling coverage, faster temperature control, and gentler handling than cube or crushed ice, flake ice enhances food safety, visual appeal, and operational efficiency. As a result, both industrial and commercial flake ice machines are now viewed as essential assets rather than optional upgrades.

This article explores how flake ice machines are reshaping food service operations in 2026, focusing on efficiency, sustainability, and expanding applications across the industry.

What Makes Flake Ice Machines Essential for Modern Food Service Industry

Modern food service operations increasingly depend on specialized ice solutions to maintain quality, safety, and efficiency. Understanding what flake ice machine technology is and how it differs from traditional ice formats explains why it has become essential across the industry. Unlike cube or crushed ice systems, flake ice machines are purpose-built for food preservation, display, and handling in demanding environments.

-

Superior Cooling Coverage and Product Protection: A flake ice machine produces soft, thin ice flakes that mold around food, delivering even cooling without bruising, freezing damage, or dehydration—ideal for temperature-sensitive products.

-

Limitations of Traditional Cube and Crushed Ice: Cube ice cools slowly and unevenly, while crushed ice often creates sharp fragments that melt inconsistently and damage delicate foods. Flake ice provides uniform cooling while retaining moisture to preserve texture and appearance.

-

Rising Food Safety and Compliance Pressures: With stricter food safety audits in 2026, flake ice machines help maintain stable holding temperatures, supporting hygiene compliance and reducing temperature-related risks.

-

Labor Efficiency and Cost Control: Flake ice simplifies workflows by eliminating manual ice handling and reducing spoilage, allowing staff to focus on higher-value tasks while maintaining consistency.

-

Enhanced Visual Merchandising and Customer Perception: Flake ice improves the presentation of seafood displays, salad bars, and chilled buffets, signaling freshness and quality to customers.

-

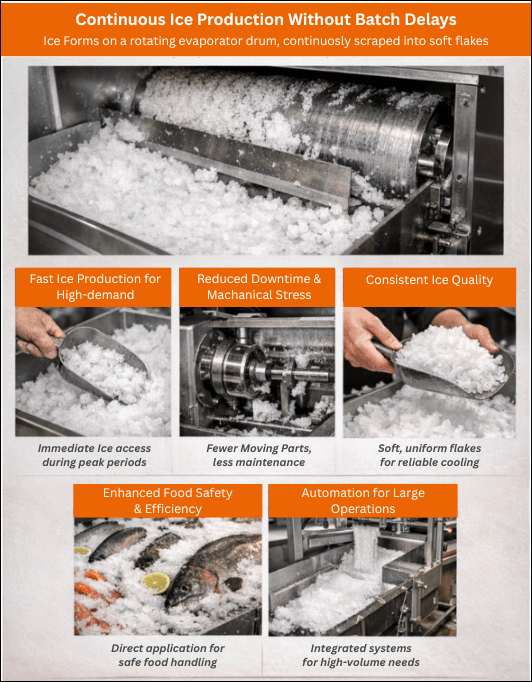

Scalability for High-Volume Operations: For large kitchens and processors, the industrial flake ice machine delivers continuous, high-capacity production that integrates seamlessly into processing and cold storage workflows.

By addressing food safety, labor efficiency, presentation quality, and scalability in a single solution, flake ice machines have become a foundational technology for modern food service operations.

Looking for dependable commercial ice machines and refrigeration replacement parts? At PartsFe CA, we offer a reliable source of high-quality commercial ice machine and refrigeration parts designed to keep foodservice equipment operating at peak performance. We make it easy to source restaurant equipment parts online, including precision-fit Manitowoc ice machine parts, like defrost timers, control boards, motors, sensors, and valves from trusted commercial brands.

Operational Efficiency Gains with Flake Ice Machine Technology

Food service operations in 2026 face constant pressure to increase output while controlling labor, time, and costs. Ice production plays a critical role in daily efficiency, and advances in flake ice technology have positioned the flake ice machine as a key driver of streamlined workflows and consistent performance.

By eliminating bottlenecks, reducing labor dependency, and ensuring consistent ice supply, flake ice machines significantly enhance operational efficiency across modern food service operations.

Sustainability and Energy Efficiency in Next-Gen Flake Ice Machines

Sustainability is no longer a competitive advantage but an operational requirement in the food service industry. In 2026, energy efficiency, water conservation, and equipment reliability are key decision factors, and next-generation flake ice machines are designed to meet these demands without sacrificing performance.

-

Lower Energy Consumption per Pound of Ice: Modern flake ice machines use advanced refrigeration systems, variable-speed compressors, and optimized evaporators to reduce energy usage while delivering higher output than legacy cube or inefficient crushed ice machines.

-

Improved Water Utilization and Reduced Waste: Thin-layer ice formation improves water-to-ice conversion rates, helping operators control utility costs, especially in regions with water restrictions.

-

Reduced Food Spoilage and Ice Melt Loss: Even cooling coverage helps maintain stable food temperatures, reducing spoilage and minimizing ice melt during holding and transport.

-

Longer Equipment Lifespan and Lower Maintenance Impact: Simplified mechanical designs reduce wear, extend equipment life, and lower maintenance frequency, supporting long-term cost control.

-

Decreased Reliance on Secondary Cooling Systems: Direct cooling with flake ice reduces the need for additional refrigeration, further lowering overall energy demand.

-

Scalable Sustainability for High-Capacity Operations: For large kitchens and processors, the industrial flake ice machine supports sustainability goals at scale while maintaining strict food safety and operational standards.

By combining energy efficiency, water conservation, and reduced waste, next-generation flake ice machines support sustainable food service operations without sacrificing reliability or performance.

Do you kow the smarter ice detection methods that improve efficiency, prevent overproduction, and enhance equipment reliability in modern foodservice operations? Check out how Next-generation ice machine monitoring.

Key Food Service Applications Driving Flake Ice Machine Adoption

The versatility of flake ice is a major reason for its rapid adoption across diverse food service segments in 2026. Its unique physical properties make it suitable for applications that extend far beyond basic beverage service.

|

Application Area |

How Flake Ice Is Used |

Operational Benefits |

|

Seafood and Fresh Food Displays |

Used in seafood counters, raw bars, and fresh produce displays |

Prevents product damage, maintains moisture, enhances food safety and visual appeal |

|

Meat and Poultry Processing |

Controls temperature during cutting, grinding, and mixing |

Reduces bacterial growth risk, improves yield, ensures consistent thermal regulation |

|

Salad Bars and Cold Buffets |

Forms a stable cooling base for self-service displays |

Even temperature distribution, slower melt rate, improved display longevity |

|

Healthcare and Institutional Food Service |

Supports therapeutic uses and patient meal service |

Gentle cooling reduces cross-contamination and supports precise temperature control |

|

Beverage and Specialty Applications |

Used in blended drinks, smoothies, and rapid chilling applications |

Faster cooling for specialty beverages without excessive dilution |

These varied use cases highlight why the commercial flake ice machine has become a standard specification rather than a niche solution.

Conclusion: The Role of Flake Ice Machines in the Future of Food Service Industry

Flake ice machines have become strategic assets that enhance food safety, efficiency, sustainability, and presentation. In 2026, the flake ice machine supports modern food service operations by providing consistent temperature control, gentle food handling, and reliable performance.

By enabling faster cooling, minimizing product damage, and maintaining stable holding conditions, flake ice technology helps operators meet operational and compliance demands. From commercial flake ice machines in restaurants to industrial flake ice machines in large-scale processing, this equipment continues to shape smarter, safer, and more sustainable food service operations.

Key Takeaways

-

Flake ice machines enhance food safety through consistent, even cooling

-

Continuous ice production improves operational efficiency during peak demand

-

Gentle ice structure preserves food quality and visual presentation

-

Energy and water pump efficient designs support sustainability goals

-

Scalable systems meet the needs of both commercial kitchens and industrial operations

References:

https://bookstation.gov/book/ice-machine-troubleshooting-guide

https://www.fcsi.org/foodservice-consultant/worldwide/ice-maker-machines-industry-trends-forecasts/

FAQs

How do flake ice machines work?

Flake ice machines freeze water in a thin layer on a refrigerated surface and continuously scrape it into soft flakes, providing a steady supply of ice without batch cycling.

What is the basic process for flake ice?

The basic process involves freezing water on an evaporator drum, mechanically removing the ice as flakes, and dispensing it directly into storage or application areas.

What is the difference between nugget and flake ice?

Nugget ice is compacted and chewable, commonly used for beverages, while flake ice is softer, thinner, and better suited for food preservation, displays, and processing applications.