How to Troubleshoot Manitowoc Ice Machine Defrost Timer Issues Step by Step

Manitowoc commercial ice machines are engineered for high-volume, consistent ice production in demanding foodservice environments. These machines operate continuously under fluctuating temperatures, heavy moisture exposure, and long run cycles. One of the most critical—but often underestimated—components supporting this performance is the defrost timer.

In Manitowoc ice machines, the defrost timer plays a central role in coordinating freeze and harvest cycles. When this component malfunctions, symptoms such as ice buildup, inconsistent ice production, extended harvest cycles, and unexpected downtime quickly appear. Understanding how the Manitowoc ice machine defrost timer works and how to troubleshoot it systematically helps operators reduce repair costs and maintain reliable operation.

This guide explains how a Manitowoc defrost timer functions, highlights common failure symptoms, outlines a step-by-step troubleshooting approach, and clarifies when repair or replacement is the best option. Whether you operate a Manitowoc ice machine in a restaurant, hotel, or institutional kitchen, this article provides practical insight to keep your equipment performing at its best.

Understanding How a Manitowoc Commercial Ice Machine Defrost Timer Works

Manitowoc commercial ice machines rely on precisely controlled freeze and harvest cycles to deliver consistent cube quality and production efficiency. At the core of this process is the defrost timer, which regulates the transition between ice formation and ice release.

-

Freeze and Harvest Cycle Control in Manitowoc Ice Machines: In Manitowoc systems, the defrost timer determines when the unit exits the freeze cycle and enters the harvest (defrost) cycle. During harvest, hot gas or electric heaters are activated to release ice from the evaporator plate. Accurate timing prevents excessive frost buildup and ensures smooth ice release.

-

Mechanical vs Electronic Defrost Timers in Manitowoc Units: Older Manitowoc ice machines commonly use mechanical defrost timers with gears and synchronous motors to advance cycles. Newer Manitowoc models often rely on electronic control boards that manage defrost timing digitally, offering improved precision and diagnostic capabilities.

-

Integration with Manitowoc Control Systems: In Manitowoc designs, the defrost timer works alongside thermostats, thickness probes, and sensors to determine harvest duration. If the timer fails to advance correctly, the ice machine may remain stuck in freeze mode or harvest mode, directly affecting ice production and energy efficiency.

-

Role of the Defrost Timer in Ice Release: The defrost timer itself does not melt ice. Instead, it signals Manitowoc’s hot gas valve or heater circuits to activate at the correct time. Proper defrost timing ensures clean ice release without overheating components or damaging the evaporator surface.

Understanding this process is essential before diagnosing or servicing defrost-related issues in Manitowoc commercial ice machines.

Looking for dependable commercial ice machines and refrigeration replacement parts? At PartsFe CA, we make it easy to source restaurant equipment parts online, supplying high-quality, precision-fit components designed to keep your equipment running efficiently and reliably. From defrost timers and control boards to motors, sensors, and valves, we stock trusted replacement parts for a wide range of commercial brands like Manitowoc, Hoshizaki, Scotsman, and Ice-O-Matic. With competitive pricing, fast shipping across Canada, and expert customer support, we help foodservice businesses minimize downtime and maintain peak performance.

Common Signs of Defrost Timer Problems in Manitowoc Ice Makers

Defrost timer issues in Manitowoc ice machines often develop gradually, producing noticeable performance changes before complete failure occurs. Recognizing these warning signs early helps prevent lost production, excessive energy use, and damage to major components, while also helping operators determine when specific Manitowoc ice machine parts may need inspection or replacement.

-

Excessive Ice or Frost Buildup on the Evaporator Plate: Heavy frost or ice accumulation on Manitowoc evaporator plates usually indicates the defrost timer is not advancing properly. Missed or delayed harvest cycles prevent normal ice release, restricting airflow and reducing heat transfer efficiency.

-

Inconsistent or Reduced Ice Production: When a Manitowoc ice machine produces ice irregularly or at reduced capacity, incorrect defrost timing is often the cause. A failing defrost timer may initiate harvest too early or too late, disrupting the machine’s production rhythm.

-

Manitowoc Ice Machine Stuck in Harvest Mode: If the unit remains in defrost (harvest) mode for extended periods, ice melts faster than it can form. This condition typically points to a defrost timer or control board that is failing to return the machine to freeze mode.

-

Continuous or Erratic Compressor Operation: Manitowoc compressors are designed to cycle predictably. Continuous running or erratic cycling places unnecessary strain on the compressor and often results from incorrect timing caused by a faulty defrost timer.

-

Clicking Sounds or Non-Advancing Mechanical Timers: On Manitowoc models with mechanical timers, clicking noises or visible gear stalling indicate internal wear. These symptoms suggest the timer motor or gear assembly is nearing failure.

-

Error Codes on Manitowoc Control Displays: Error codes shown on the Manitowoc ice machine display help identify issues with defrost and harvest cycles. These control display alerts directly connect to common signs of defrost timer problems in Manitowoc ice makers, including delayed ice release, abnormal cycle timing, and reduced ice output.

Explore the key warning indicators that reveal when maintenance is no longer optional: 5 signs you should clean or replace your ice machine.

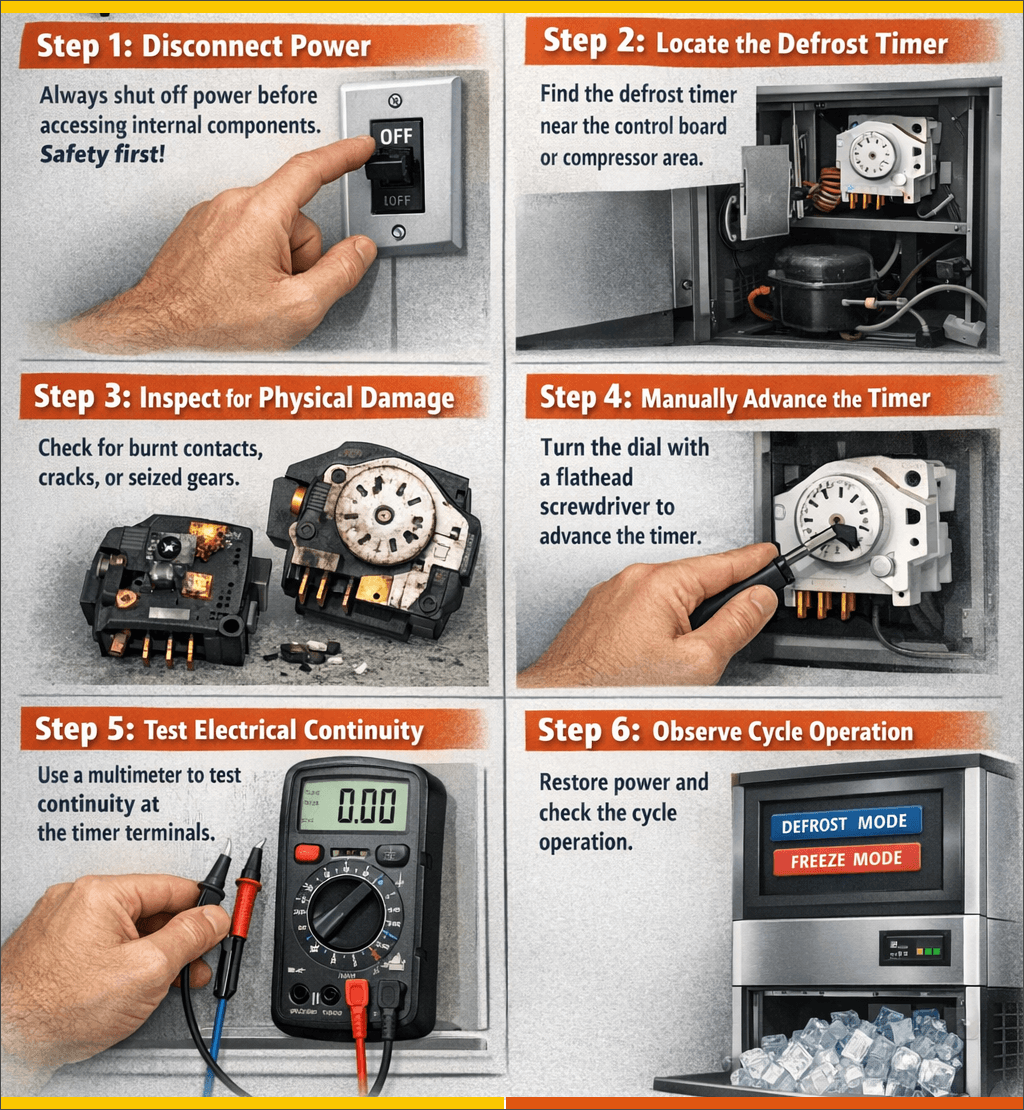

Step-by-Step Process to Troubleshoot a Manitowoc Defrost Timer

Troubleshooting a Manitowoc ice machine defrost timer should always follow a structured and safety-conscious process. While exact procedures vary by model, the following steps apply broadly across Manitowoc commercial units.

This systematic approach helps determine whether the issue originates with the defrost timer itself or with related components such as thermostats, thickness probes, or the main control board.

Causes Behind Commercial Ice Machine Defrost Timer Failures

Manitowoc ice machines operate in harsh environments where moisture, temperature fluctuations, and continuous operation accelerate component wear. Defrost timer failures typically stem from predictable causes tied to operating conditions and maintenance habits.

-

High Humidity and Environmental Exposure: Manitowoc ice machines are exposed to moisture, grease, and airborne contaminants. Over time, humidity and debris can corrode contacts or damage internal timer components, shortening the lifespan of the defrost timer.

-

Mechanical Wear in Manitowoc Mechanical Timers: Mechanical defrost timers use gears and motors that wear with age. As these components degrade, timing accuracy suffers, leading to delayed harvest cycles or incomplete defrosting.

-

Electronic Timer and Control Board Sensitivity: Electronic defrost timers and control boards used in newer Manitowoc models offer precision but are vulnerable to moisture and power irregularities. Voltage spikes or condensation can damage circuitry and disrupt defrost timing.

-

Poor Maintenance and Restricted Airflow: Dirty condenser coils or blocked ventilation cause Manitowoc ice machines to run longer cycles. Extended run times increase stress on defrost timing components and accelerate failure.

-

Inconsistent Power Supply: Facilities without surge protection or stable voltage often experience premature electronic failures. Power fluctuations can corrupt defrost timing logic or permanently damage electronic control boards.

Addressing these root causes helps prevent repeated defrost timer failures and extends the service life of Manitowoc ice machines.

When to Repair or Replace the Defrost Timer in Your Ice Machine

Deciding whether to repair or replace a Manitowoc defrost timer depends on timer type, failure severity, and overall machine condition.

|

Factor |

When to Repair |

When to Replace |

|

Mechanical Timer Condition |

Minor contact wear or slow advancement with no electrical damage. |

Severe wear, inconsistent timing, or recurring failures affecting ice production. |

|

Electronic Defrost Timer Failure |

Rarely recommended, as internal components are sealed and not serviceable. |

Circuit damage, failure to initiate defrost cycles, or manufacturer repair limitations. |

|

Ice Machine Age & Usage |

The unit is relatively new with a good maintenance history. |

The machine is nearing the end of its expected service life or has a history of frequent repairs. |

|

Frost & Defrost Cycle Issues |

Occasional frost buildup resolved after adjustment or calibration. |

Repeated frost buildup or defrost issues shortly after repairs, indicating timer malfunction. |

Making informed repair-versus-replacement decisions protects compressors, evaporators, and refrigeration circuits from secondary damage.

Check out a complete, practical breakdown that explains when routine cleaning is enough and when full replacement makes more sense: Clean or replace ice machine: Here’s everything you need to know.

Conclusion: Keeping Manitowoc Commercial Ice Machines Running Smoothly

Manitowoc commercial ice machines are built for reliability, but optimal performance depends on precise system control and proactive maintenance. The defrost timer is a critical component, and even minor timing errors can disrupt ice production, increase energy consumption, and accelerate equipment wear.

Key Takeaways

-

Understanding Manitowoc defrost timer operation improves diagnostic accuracy

-

Ice buildup, erratic cycling, and low output are early warning signs

-

Structured troubleshooting isolates timer, thermostat, or control board faults

-

Regular cleaning and inspections reduce stress on defrost components

-

Timely defrost timer replacement prevents costly secondary failures

Whether addressing an active issue or preventing future downtime, proper defrost timer management is essential for maintaining reliable Manitowoc ice production in high-demand environments.

FAQs

How do you determine a defective defrost timer in a Manitowoc ice machine?

A defective Manitowoc defrost timer often fails to advance cycles, causes excessive frost buildup, or shows no continuity when tested with a multimeter.

What are the symptoms of a bad defrost thermostat in Manitowoc units?

A failed defrost thermostat may prevent hot gas or heaters from activating, allowing ice to accumulate even when the timer appears functional.

How can you tell if a Manitowoc defrost control board is bad?

If harvest cycles do not initiate despite a working timer and thermostat, the Manitowoc control board or electronic defrost timer may be faulty.

How many times can frozen meat be defrosted?

From a food safety perspective, frozen meat should ideally be defrosted once. Repeated freezing and thawing increases bacterial risk. While commonly discussed in refrigeration contexts, this topic is unrelated to ice machine defrost systems.