How to Identify and Troubleshoot Parker Solenoid Valve Issues: A Step-by-Step Guide

Parker solenoid valves are essential components in industrial and commercial fluid control systems. They regulate the flow of liquids and gases with precision, ensuring smooth operation in applications such as hydraulics, pneumatics, water treatment, and manufacturing. Malfunctions in these valves can cause system inefficiencies, equipment damage, or costly downtime, making it crucial for maintenance teams, engineers, and operators to understand how to identify and troubleshoot potential issues effectively.

Troubleshooting Parker solenoid valves involves recognizing warning signs, diagnosing electrical and mechanical faults, and addressing flow, contamination, or operational problems. By systematically inspecting and maintaining these valves, minor issues can be corrected before they escalate. This step-by-step guide provides practical solutions to ensure reliable valve performance and maintain optimal system efficiency.

Understanding Parker Solenoid Valves and How They Work

Parker solenoid valves precisely control water, gas, or steam flow in commercial kitchen equipment. They ensure efficient, safe, and reliable operation for appliances like ovens, dishwashers, and coffee machines.

How they work:

-

Electrical Activation: When powered, the coil generates a magnetic field.

-

Plunger Movement: The magnetic field pulls or pushes a plunger to open or close the valve.

-

Flow Control: Opening the valve allows liquid or gas to pass; closing it stops the flow.

-

Spring Return: When the coil is de-energized, a spring returns the plunger to its default position (normally open or closed).

-

Rapid Response: The quick actuation ensures consistent operation in high-demand kitchen environments.

This simple electromagnetic mechanism explains how a Parker solenoid valve works, enabling commercial kitchens to manage fluids and gases safely and efficiently.

Looking for genuine solenoid valve parts? PartsFe CA offers top-quality components like solenoid valves, gas safety valves, and solenoid valve coils from trusted brands, including Parker Hannifin, Champion, and Imperial, to keep your systems running smoothly. Enjoy fast shipping and expert support with every order!

How to Recognize Warning Signs of Parker Solenoid Valve Problems

Early identification of problems can save time, money, and equipment. Recognizing warning signs allows preventive action before failures escalate.

Electrical Warning Signs

-

Valve Not Activating: Coil fails to energize despite correct voltage.

-

Burnt Smell or Smoke: Indicates overheating or a shorted coil.

-

Intermittent Operation: Valve responds inconsistently, suggesting wiring or coil issues.

Mechanical Warning Signs

-

Sticking Plunger: Valve opens or closes sluggishly.

-

Leaks: Damaged seals or worn O-rings allow fluid or air to escape.

-

Unusual Noise: Buzzing, clicking, or rattling during operation signals internal friction or misalignment.

Flow and Contamination Signs

-

Reduced Flow or Pressure Drops: Suggests clogged ports or passageways.

-

Debris or Sediment: Visible contamination inside the valve or fluid system.

-

Corrosion: Rust or chemical wear indicates material degradation.

Installation and Operational Signs

-

Incorrect Mounting Orientation: The Valve may fail to operate properly if installed incorrectly.

-

Wrong Valve Size: Flow or pressure irregularities due to mismatched system requirements.

-

Extreme Temperature Exposure: Excessive heat or cold can stiffen seals or damage components.

Proper Parker solenoid valve installation is crucial to avoid many of these common issues and ensure reliable operation.

Common Problems in Parker Solenoid Valves

Even reliable Parker solenoid valves can face issues over time. Early detection of common problems ensures smooth operation in commercial kitchen equipment.

Common Problems:

-

Coil Burnout: Overheating from continuous power or voltage spikes can render the coil inoperative.

-

Leaking Valve Seats or Seals: Worn or damaged seals allow water, gas, or steam to escape.

-

Sticking Plunger or Armature: Mineral deposits, grease buildup, or corrosion cause sluggish or failed valve movement.

-

Clogged Orifices or Ports: Food debris, hard water deposits, or sediment block fluid or gas flow.

-

Electrical Failures: Broken wires, loose connections, or short circuits prevent proper valve activation.

-

Valve Not Responding: Improper voltage, incorrect coil rating, or mechanical obstruction stops operation.

-

Corrosion of Metal Components: Exposure to steam, harsh cleaning chemicals, or acidic liquids degrades internal parts.

Regular inspection and maintenance prevent these issues, keeping kitchen equipment efficient and safe.

Essential Tools and Safety Precautions for Troubleshooting Parker Solenoid Valves

Effective Parker solenoid valve troubleshooting requires the right tools and strict adherence to safety protocols.

Essential Tools

-

Multimeter: For checking coil voltage, continuity, and electrical resistance.

-

Pressure Gauges: To measure system pressure and identify flow issues.

-

Wrenches and Screwdrivers: For disassembly and inspection.

-

Cleaning Brushes and Inspection Tools: To remove debris and inspect internal parts.

Safety Precautions

-

Always de-energize electrical systems before working on the valve.

-

Use personal protective equipment (PPE), including gloves and safety goggles.

-

Follow manufacturer guidelines for pressure release and valve disassembly.

-

Maintain a clean work environment to prevent contamination.

Diagnosing Electrical and Mechanical Problems in Parker Solenoid Valves

Early detection of electrical and mechanical issues in Parker solenoid valves keeps commercial kitchen equipment running smoothly. Quick identification prevents downtime and leaks.

1. Coil Shorting Due to Steam Exposure

-

Symptoms: Valve fails intermittently; burnt smell during operation.

-

Cause: Excessive steam from dishwashers or steam ovens condenses inside the coil casing.

-

Fix: Dry the coil and inspect insulation to ensure safety. Replace the coil if damaged; consider adding protective covers to prevent future exposure.

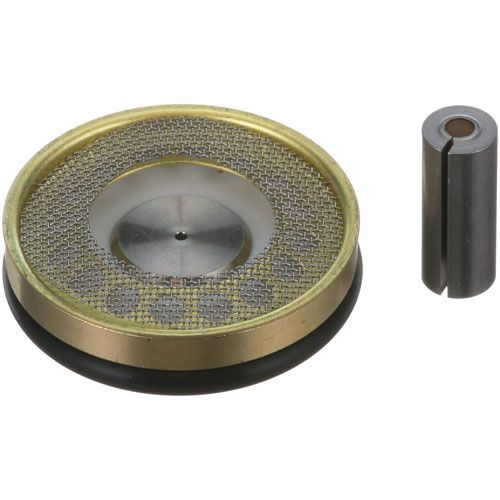

2. Plunger Sticking from Mineral Deposits

-

Symptoms: Slow valve response or incomplete opening/closing.

-

Cause: Hard water or food debris builds up on the plunger and inner sleeve.

-

Fix: Remove and soak the valve in a descaling solution to dissolve deposits. Clean thoroughly and lubricate as recommended by the manufacturer.

3. Seal Degradation from Cleaning Chemicals

-

Symptoms: Leaks of water, gas, or steam around the valve body.

-

Cause: Frequent exposure to harsh detergents or acidic cleaners in kitchen environments.

-

Fix: Replace the seals or O-rings with chemical-resistant variants. Ensure regular inspection to prevent recurring leaks.

4. Spring Fatigue from High-Cycle Operations

-

Symptoms: Valve fails to return fully; sluggish actuation.

-

Cause: Continuous opening/closing cycles in high-demand kitchen appliances.

-

Fix: Replace springs with the correct rating to restore normal operation. Avoid prolonged continuous cycles to extend spring life.

5. Wiring Corrosion from Moisture or Steam

-

Symptoms: Intermittent or complete valve failure.

-

Cause: High humidity or condensation on terminals in commercial kitchens.

-

Fix: Clean terminals and apply protective coatings. Replace damaged wiring to restore reliable electrical connectivity.

6. Misalignment of Plunger from Shock or Vibration

-

Symptoms: Clicking or rattling noise; partial valve operation.

-

Cause: Frequent movement, vibration, or accidental impacts in kitchen equipment.

-

Fix: Re-align the plunger and check internal guides for wear. Replace worn components to prevent recurring misalignment.

7. Internal Blockage from Food Particles or Sediment

-

Symptoms: Reduced flow, uneven heating, or inconsistent steam delivery.

-

Cause: Small debris from water lines, coffee machines, or dishwasher residues.

-

Fix: Disassemble the valve and clean all ports thoroughly. Flush the system and consider installing inline strainers to prevent future blockages.

Check out this guide on how to reset grill pressure regulators for quick steps to restore proper gas flow and safe grilling.

Addressing Unique Flow, Contamination, and Operational Issues in Parker Solenoid Valves

In commercial kitchens, some solenoid valve problems are subtle and often overlooked, but they can impact performance and safety.

Plunger Magnetization

-

Signs: Valve sticks intermittently or opens/closes unpredictably.

-

Cause: Continuous operation causes the plunger to become weakly magnetized, affecting movement.

-

Solution:

-

Demagnetize the plunger using manufacturer-approved methods.

-

Inspect and replace if magnetization persists.

-

Lubricate the plunger according to specs to reduce friction.

-

Check surrounding components for magnetic interference.

Micro-Leaks from Threaded Fittings

-

Signs: Slight steam or water escaping near threaded joints, not visible leaks.

-

Cause: Vibrations or improper torque on fittings over time.

-

Solution:

-

Re-torque fittings according to manufacturer specs.

-

Apply food-safe thread sealant if needed.

-

Inspect adjacent fittings for loosening.

-

Monitor over time to catch recurring leaks early.

Plunger Binding Due to Thermal Expansion

-

Signs: Valve operates normally when cold but sticks during high-temperature operation.

-

Cause: Metal components expand differently, causing tight tolerances to bind the plunger.

-

Solution:

-

Inspect valve materials for thermal mismatch.

-

Replace with heat-tolerant valves or adjust installation spacing.

-

Allow cooling periods between high-temperature cycles.

-

Check plunger alignment after repeated thermal cycles.

Coil Insulation Degradation from Cleaning Sprays

Signs: Coil sparks or trips breakers after heavy cleaning cycles.

Cause: Frequent exposure to aerosolized cleaning chemicals degrades insulation.

Solution:

-

Replace the coil and install protective covers.

-

Minimize direct exposure during cleaning cycles.

-

Inspect coil insulation regularly for cracks or discoloration.

-

Ensure proper ventilation to reduce chemical buildup.

Parker solenoid valve coil should be checked regularly to avoid electrical failures.

Partial Obstruction by Air Bubbles in Water Lines

-

Signs: Valve opens, but water flow fluctuates or sputters.

-

Cause: Trapped air in high-pressure lines affects valve operation.

-

Solution:

-

Bleed air from the lines.

-

Install air-release valves or adjust system design.

-

Check for leaks that may introduce air.

-

Run water at high flow to flush remaining bubbles.

Seal Hardening from Intermittent Steam Exposure

-

Signs: Valve leaks after periods of operation but functions normally after cooling.

-

Cause: Periodic steam exposure dries or hardens seals over time.

-

Solution:

-

Replace seals with high-temperature rated versions.

-

Adjust the system to maintain consistent steam levels.

-

Inspect seals regularly for cracking or stiffness.

-

Lubricate seals with manufacturer-approved high-temp grease.

Tips to Ensure Reliable Parker Solenoid Valve Operation After Troubleshooting

Maintaining optimal performance after troubleshooting prevents downtime and ensures consistent operation in commercial kitchen equipment. Implementing these proactive strategies helps extend valve life and reliability.

-

Verify Coil Health Regularly: Check coil resistance and insulation to prevent failures, especially for Parker solenoid valve 12V models.

-

Use High-Temperature Rated Seals: Replace worn seals with heat-resistant variants to withstand steam ovens and dishwashers.

-

Install Inline Strainers: Prevent food particles, scale, and debris from entering the valve and causing blockages.

-

Monitor Thermal Expansion Effects: Ensure valves are installed with proper clearance to avoid plunger binding in high-temperature operations.

-

Protect Coils from Cleaning Sprays: Use shields or covers to prevent chemical damage during aggressive kitchen cleaning cycles.

-

Check for Magnetic Interference: Keep solenoid plungers away from strong magnets or electronic devices that can cause magnetization issues.

-

Consult the Manual: Always refer to the Parker solenoid valve manual for specific installation, maintenance, and troubleshooting instructions to ensure proper handling.

-

Perform Functional Cycling Tests: Periodically operate valves under controlled conditions to identify intermittent sticking or sluggish movement.

-

Document Maintenance History: Track inspections, replacements, and issues to predict potential failures and plan preventive actions.

Check out this guide on how to clean grill grates for easy, effective tips to keep your grill spotless and ready to use.

A Proactive Approach to Parker Solenoid Valve Troubleshooting

Proper identification and troubleshooting of Parker solenoid valve issues are essential to maintaining system reliability and minimizing downtime. From diagnosing electrical faults to addressing flow and contamination problems, a step-by-step approach ensures accurate solutions and restores optimal performance.

By utilizing the right tools, adhering to safety precautions, and implementing preventive measures, you can prolong the life of your valves and prevent recurring issues. Regular maintenance, timely replacement of worn parts, and adherence to manufacturer guidelines will help keep your equipment running smoothly in demanding environments, such as commercial kitchens or industrial systems.

FAQs

How do I know if my Parker solenoid valve is faulty?

Common signs include the valve not activating, leaking, unusual noises, or inconsistent operation. Testing the coil and inspecting seals can help diagnose issues.

What should I do if my valve isn’t opening or closing properly?

Check for electrical supply issues, mechanical obstructions, and proper coil function. Cleaning or replacing worn parts may be necessary.

Can I repair a Parker solenoid valve myself?

Basic troubleshooting, like cleaning or replacing a seal, is possible, but complex electrical or mechanical repairs should be done by professionals to avoid damage.

Why is my Parker solenoid valve not working?

Common reasons include coil failure, wiring issues, or clogged valve components preventing proper operation. Regular maintenance and troubleshooting help identify and fix these problems quickly.