Scotsman Ice Machine Troubleshooting: Complete Guide for Commercial Operations

Commercial kitchens rely on ice machines as essential operational equipment, not just for convenience. From restaurants and bars to hotels and hospitals, consistent ice production supports beverage service, food safety, and efficient daily operations. Scotsman ice machines are recognized for durability and performance, but even high-quality systems require proper understanding, maintenance, and troubleshooting to operate reliably in high-volume environments. Understanding how a Scotsman ice machine works and recognizing early warning signs helps reduce downtime, control repair costs, and extend equipment lifespan. It also enables informed decisions about Scotsman ice machine repair, identifying faulty Scotsman ice machine parts, and selecting appropriate replacement components.

This guide outlines how Scotsman ice machines operate, common commercial issues, and step-by-step Scotsman ice machine troubleshooting techniques to help operators maintain dependable ice production.

Understanding How Scotsman Ice Machines Work

Before attempting any troubleshooting or repair, it is essential to understand how a Scotsman ice machine operates. Knowing the complete ice-making cycle allows technicians and operators to pinpoint failures accurately.

-

Water Intake and Filtration: The process begins when water enters the machine through the inlet valve and passes through a filtration system. Clean, properly pressurized water is critical for consistent ice formation and machine longevity. Restricted filters or poor water quality directly impact ice clarity and output.

-

Freezing Cycle on the Evaporator: Filtered water flows evenly across the evaporator plate. Refrigerant circulating through the evaporator absorbs heat, freezing the water into a uniform ice slab or cubes. Any imbalance in water distribution or refrigerant flow affects ice thickness and shape.

-

Harvest Cycle and Ice Release: Once the ice reaches the correct thickness, the machine initiates the harvest cycle. Hot gas or warm water loosens the ice from the evaporator surface, allowing it to drop into the storage bin. Harvest failures often indicate valve, sensor, or control board issues.

-

Storage Bin and Level Detection: Bin sensors monitor ice levels to prevent overproduction. If these sensors malfunction, the machine may stop producing ice prematurely or fail to shut off when the bin is full.

Understanding this workflow forms the foundation for all Scotsman ice machine troubleshooting procedures.

Looking to repair or maintain your commercial ice machine with reliable, high-quality parts? PartsFe CA makes it easy to find restaurant equipment parts online, offering premium-grade Scotsman ice machine replacement parts such as water pumps, control boards, sensors, valves, and other essential components from trusted commercial equipment brands.

Identifying Common Scotsman Ice Machine Issues in High-Volume Kitchens

High-demand commercial kitchens place continuous stress on ice machines, making certain problems more common than others.

Low or Inconsistent Ice Production: Reduced output is often caused by scaled evaporators, clogged filters, insufficient water pressure, or failing Scotsman ice machine parts such as inlet valves and pumps.

Irregular Ice Shape or Thickness: Thin, hollow, or malformed ice typically points to water distribution problems, improper freeze times, or sensor calibration issues.

Unexpected Shutdowns: Machines that shut off without warning may be reacting to faulty bin sensors, high-pressure safety switches, or electrical control faults.

Unusual Noise or Vibration: Grinding, buzzing, or rattling sounds usually indicate mechanical wear in fan motors, compressors, or bearings, requiring immediate inspection.

Water Leaks and Overflow: Leaks are commonly linked to blocked drains, cracked hoses, or improper procedures for how to drain Scotsman ice machine systems.

Recognizing these symptoms early allows faster intervention and prevents cascading failures.

Diagnosing Water Supply, Filtration, and Drainage Problems in Scotsman Ice Machines

Water-related issues account for a significant percentage of service calls involving Scotsman ice machine repair. Since ice machines rely heavily on clean, consistent water flow, even small disruptions can affect performance.

Water Supply Issues: Insufficient water pressure or a partially closed supply valve can prevent the evaporator from filling correctly. This leads to thin ice slabs, incomplete cubes, or extended freeze cycles. Always verify that the water supply meets manufacturer specifications.

Filtration Problems: Scotsman recommends regular filter replacement to protect internal components. A clogged filter restricts flow, reduces ice clarity, and accelerates scale buildup. Neglecting filtration often results in premature failure of Scotsman ice machine parts such as inlet valves and evaporators.

Drainage Failures: Improper drainage is another frequent concern. A blocked or improperly installed drain line can cause water to back up into the bin or machine compartment. Understanding how to drain Scotsman ice machine systems correctly is critical during both troubleshooting and routine maintenance.

To diagnose drainage issues:

-

Inspect the drain hose for kinks or obstructions

-

Ensure proper slope for gravity drains

-

Clean mineral deposits from drain fittings

-

Verify pump operation on pump-assisted models

Addressing water supply, filtration, and drainage problems early prevents sanitation issues and protects costly mechanical components.

Explore commercial ice machine air filter replacement: ultimate guide to keeping your equipment efficient and reliable.

Detecting Mechanical and Electrical Failures in Scotsman Ice Machines

Mechanical and electrical failures are more complex and often require structured testing.

-

Compressor and Condenser Evaluation: A failing compressor reduces cooling efficiency and ice output. Dirty condensers or defective condenser fans can cause high-pressure shutdowns, especially in hot kitchen environments.

-

Fan Motors and Moving Components: Worn fan motors restrict airflow, leading to overheating. Bearings and drive components should be checked for wear and abnormal noise.

-

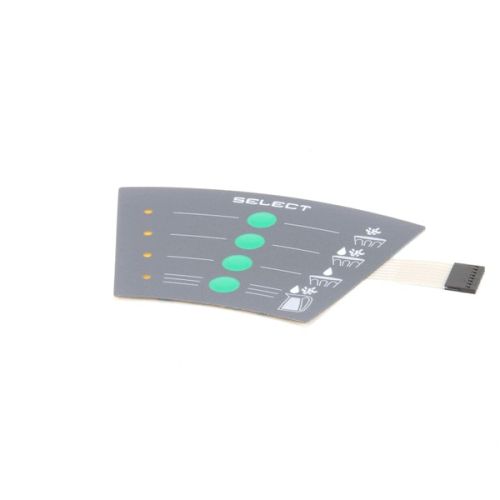

Control Boards and Sensors: Faulty control boards can disrupt cycle timing, while defective bin sensors may stop production unnecessarily. Reference the Scotsman ice machine troubleshooting manual for diagnostic codes and test procedures.

-

Electrical Connections and Wiring: Loose, corroded, or damaged wiring can cause intermittent failures that are difficult to trace without systematic inspection.

When these components fail, using genuine Scotsman ice machine replacement parts ensures compatibility and reliable operation.

Step-by-Step Scotsman Ice Machine Troubleshooting Techniques for Efficient Ice Production

A structured approach to troubleshooting minimizes guesswork and ensures efficient resolution. Below is a practical framework used by service professionals.

Step 1: Visual Inspection

Begin by inspecting the machine for obvious issues like water leaks, loose connections, dirty condensers, or error indicators.

Step 2: Verify Water and Airflow

Confirm that water pressure is adequate and filters are clean. Check condenser airflow and ensure vents are unobstructed.

Step 3: Observe the Ice-Making Cycle

Watch a full freeze and harvest cycle. Delays, incomplete ice release, or abnormal noises provide valuable diagnostic clues.

Step 4: Consult the Troubleshooting Manual

Referencing the Scotsman ice machine troubleshooting manual helps decode error codes and identify component-specific issues.

Step 5: Test Components

Use appropriate tools to test sensors, valves, and electrical continuity. Replace failed components with genuine Scotsman ice machine replacement parts to ensure compatibility and reliability.

Step 6: Perform Drain and Cleaning Procedures

If scaling or drainage issues are present, follow manufacturer-recommended cleaning and draining procedures. Knowing exactly how to drain Scotsman ice machine systems is essential during this step. This systematic process supports faster repairs and reduces unnecessary part replacement.

Common Scotsman Ice Machine Problems: Causes & Troubleshooting

|

Problem |

Symptoms |

Possible Causes |

Troubleshooting Steps |

|

Low Ice Production |

Slow or insufficient ice |

Dirty condenser, low water pressure |

Clean condenser, verify supply |

|

Ice Machine Leaking |

Water around the unit |

Blocked drain, cracked hose |

Clear the drain, inspect the hoses |

|

Ice Not Releasing |

Ice stuck on the evaporator |

Faulty harvest cycle, scale buildup |

Descale evaporator |

|

Machine Won’t Start |

No response |

Control board failure, electrical issue |

Check power, inspect control board |

|

Poor Ice Quality |

Cloudy or soft ice |

Dirty filter, scale deposits |

Replace filter, clean system |

When these steps fail to resolve the issue, professional Scotsman ice machine repair is recommended.

Preventive Maintenance Strategies to Maximize Scotsman Ice Machine Performance

Preventive maintenance is the most effective way to minimize emergency Scotsman ice machine repair and extend equipment lifespan. In commercial environments, a proactive maintenance schedule is not optional—it is essential.

Key preventive strategies include:

-

Routine Cleaning: Clean evaporators, bins, and water lines according to manufacturer guidelines to prevent scale and biofilm buildup.

-

Filter Replacement: Change water filters at recommended intervals to protect internal Scotsman ice machine parts.

-

Condenser Maintenance: Clean air-cooled condensers regularly to maintain proper heat dissipation.

-

Drain Inspection: Periodically inspect drain lines and pumps to prevent blockages and overflows.

-

Operational Monitoring: Track ice production volume and cycle times to detect performance degradation early.

Training staff to recognize early warning signs and document issues ensures small problems are addressed before escalating. Preventive maintenance not only reduces repair costs but also ensures consistent ice quality and food safety compliance.

Explore how to maintain and replace a commercial ice machine water pump for reliable performance and longer equipment life.

Conclusion

Scotsman ice machines are engineered for demanding commercial operations, but consistent performance depends on proper understanding, timely troubleshooting, and disciplined maintenance. By learning how these machines work, identifying common operational issues, and applying structured Scotsman ice machine troubleshooting techniques, operators can significantly reduce downtime and extend equipment life.

Key takeaways include:

-

Understanding the ice-making cycle simplifies diagnostics and repair decisions.

-

Water quality, filtration, and drainage are leading causes of performance issues.

-

Mechanical and electrical failures require systematic testing and accurate diagnosis.

-

Using the Scotsman ice machine troubleshooting manual improves repair efficiency.

-

Preventive maintenance minimizes the need for emergency Scotsman ice machine repair and protects critical components.

Whether you are learning how to repair a Scotsman ice machine, sourcing reliable Scotsman ice machine replacement parts, or simply aiming to maintain peak performance, a proactive, informed approach is the foundation of reliable ice production in commercial operations.

FAQs

How to drain a Scotsman ice machine?

Turn off the unit, shut off the water supply, and follow the draining procedure outlined in the service manual. This typically involves flushing residual water from internal lines and reservoirs.

How to repair a Scotsman ice machine?

Begin with a structured diagnosis using visual inspection, cycle monitoring, and component testing. Minor issues can be handled internally, while major faults require professional Scotsman ice machine repair using OEM parts.

How to hard reset a Scotsman ice machine?

Power off the machine, disconnect it from power for several minutes, then restart it. This clears temporary control errors but does not fix mechanical or water-related problems.