Commercial Oven Control Board Repair: Everything You Need to Know

Commercial oven control boards are essential for the smooth operation of any commercial kitchen. These complex components regulate temperature, cooking time, and various other functions, ensuring your oven performs at its best. When a control board malfunctions, it can lead to costly downtime and disruption in daily operations. Repairing or replacing the control board is often more economical than purchasing a new oven, but it requires knowledge of electrical systems and the specific oven model. In this guide, we'll walk you through common issues with commercial oven control boards, how to diagnose them, and when to call in a professional technician. Understanding these repairs can help save time, money, and keep your kitchen running efficiently.

Understanding the Role of a Commercial Oven Control Board

The commercial oven's control board functions as the central control system which regulates all essential operational functions of the appliance. The control board operates by managing heating elements while controlling temperature settings and managing cooking cycles and timer operations. The user interface interpretation through the control board leads to component instructions that keep the oven both efficient and functional. Different types of sensors connect to the control board which enables the oven to monitor temperature shifts and ensure accurate heat performance.

The control boards in modern commercial ovens include features such as programmable settings and touch screens and self-diagnostic systems. The innovations enhance usability and dependability because these features matter most in high-speed kitchen operations. The control board maintains safety functions by stopping overheating conditions while it ensures all components like fans and heating elements work in sync. The control board's operation requires full comprehension because board failures can cause uneven cooking and total oven breakdown. Early detection of these signs helps determine if the oven requires repair or needs replacement.

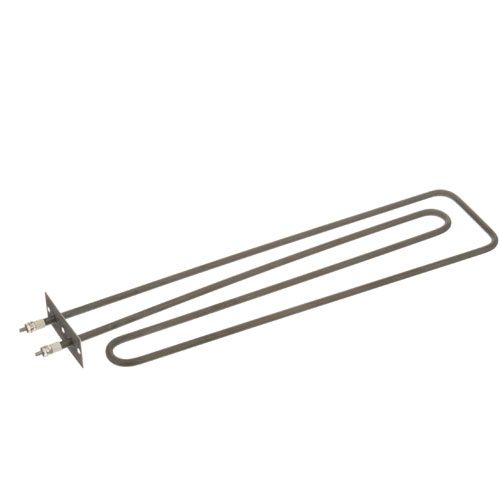

Looking to fix your commercial oven control board? PartsFe CA has you covered with top-quality oven parts for Vulcan, Wolf, and TurboChef ovens. Explore our range of control boards, thermostats, and heating elements for the best repair solutions. Trust us for fast shipping and durable parts to get your oven back to peak performance!

Signs Your Commercial Oven Control Board Needs Repair

The identification of commercial oven control board malfunctioning remains essential to prevent kitchen equipment breakdown and operational interruptions. A damaged control board creates operational problems which result in high repair expenses and possibly forces you to replace your equipment. The following signs indicate your control board requires attention:

-

Inconsistent Temperature: The oven faces difficulties with temperature control because the control board fails to communicate properly with temperature sensors. The resulting cooking problems include food that is not properly cooked and areas that remain raw.

-

Failure to Turn On/Off: A control board malfunction results in power failure when the oven should turn on or off. The oven either needs additional cooking time or fails to start at all because of this problem.

-

Erratic Display Behavior: When the control board fails to transmit correct signals to the user interface the display becomes blank or flickers or malfunctions which prevents users from setting or monitoring cooking settings.

-

Unexplained Error Codes: The appearance of error codes without obvious reasons indicates that the control board either sends incorrect data or develops internal problems which disrupts oven performance.

-

Unusual Noises: Unusual buzzing or clicking or humming noises from the oven indicate that the control board struggles to operate the oven components because of electrical problems or internal malfunctions.

For more insights on troubleshooting heating element issues that can affect your oven's performance, check out this guide on how to fix a broken heating element in a commercial oven.

Common Causes of Commercial Oven Control Board Failures

The control board in commercial ovens fails due to multiple reasons which affect oven performance and result in expensive maintenance costs. Knowing the typical reasons for control board failure enables quick issue detection to decide between repair or replacement needs.

-

Electrical Surges: The control board of an oven faces severe damage from power surges and voltage fluctuations unless it has proper protection from a surge protector. Electrical spikes that occur in the system can damage board components until they fail which results in unpredictable behavior or complete system breakdown.

-

Overheating: The high operating temperatures of commercial ovens lead to control board overheating when exposed to heat for extended periods. The board's sensitive components become damaged when exposed to excessive heat which causes operational problems including intermittent behavior. The oven's ventilation system and airflow become major factors that worsen this problem.

-

Wear and Tear: The continuous operation of commercial ovens eventually causes the control board to naturally degrade. The operational integrity of the system declines when components degrade while connections weaken and solder joints break. High-use commercial environments often experience this problem because their ovens operate continuously throughout the day.

-

Moisture or Contaminants: The control board inside the oven becomes vulnerable to damage when exposed to moisture or grease or any other contaminant. Control boards succumb to corrosion issues and short circuits from moisture exposure simultaneously although component obstruction by grease leads to breakdowns.

-

Faulty Wiring or Connections: The communication between the control board and other oven components will be disrupted when wiring is loose or damaged or when connections are poor or cables are broken. The control board experiences inconsistent performance or complete failure when these issues occur.

Diagnosing Issues with a Commercial Oven Control Board

The systematic method is needed to diagnose problems with commercial oven control boards for proper identification of the issue. The process of oven control board troubleshooting enables users to identify malfunction sources while avoiding unnecessary expenses.

Check the Power Supply

The oven fails to turn on because of either a defective power supply or broken components.

Solution: Check for damage in the power cord and inspect both circuit breakers and fuses. The control board needs professional inspection because the problem seems to be located within the board itself.

Examine the Display Screen and Control Panel

A malfunction becomes apparent through a display that remains blank or flickers while also showing unusual error messages on the control panel.

Solution: Use the user manual to understand error codes. The display malfunction or unclear error codes require inspection of oven control panel connections because damaged or loose components may be the cause.

Test the Temperature Sensors

The temperature sensors will produce incorrect readings which leads to inaccurate or inconsistent temperatures.

Solution: A multimeter should be used to inspect temperature sensors or thermocouples. The replacement of faulty temperature sensors will ensure accurate regulation and prevent cooking inconsistencies.

Check for Loose Connections

The oven will experience erratic behavior and failure when wiring connections become loose or damaged.

Solution: Check the wiring connections between the control board and all components including fans, heating elements and sensors. You should check and fix all faulty connections to ensure proper system operation.

Inspect the Control Board

Physical damage that causes burn marks or breaks components on the control board leads to system malfunctions.

Solution: Check the oven circuit board for both burnt and discolored areas and broken components through visual inspection. The control board requires replacement or repair when visible damage appears to achieve full operational capability.

Test the Relay and Capacitors

The power system and temperature stability may be affected by defective relays or capacitors.

Solution: A multimeter should be used to check the oven control board relays and capacitors for their ability to conduct electricity. Proper power distribution together with overheating prevention and start-up reliability should be achieved by replacing defective components.

Steps to Commercial Oven Control Board Repair

The repair process for commercial oven control boards needs both detailed examination and sequential steps to correctly identify and solve the problem. The following steps outline the necessary process for fixing a malfunctioning control board:

Step 1: Turn Off the Power

Begin all repair tasks by disconnecting power from the oven completely to prevent electrical hazards and additional component damage.

Step 2: Remove the Control Board

The control panel or access panel needs to be carefully removed to access the control board inside the oven. Note the locations of each part before you unscrew or detach multiple components from the system. Touch the board gently to prevent breaking its wiring connections and electrical components.

Step 3: Inspect for Visible Damage

Check the control board for evidence of damage by looking for burnt components and scorched areas and broken solder joints. The presence of damage on the control board indicates that you should consider replacing it. A minimal amount of damage allows you to try fixing the board.

Step 4: Test the Components

A multimeter should be used to check the continuity of all components including relays and capacitors on the control board. Any faulty components or irregular readings will require replacement of the affected parts. The control board fails because of this issue.

Step 5: Checking all Wiring and Connections

Check all wiring that connects to the control board to identify loose or frayed or damaged wires. Secure all connections properly because loose connections will lead to erratic behavior or complete failure.

Step 6: Clean the Board

Use a soft brush or compressed air to remove grease and dirt and dry moisture from the control board surface. The board's functionality can be negatively impacted by moisture or any type of contamination.

Step 7: Replace Damaged Components

For your oven model you should replace burnt capacitors or faulty relays with the exact parts needed for repair. Use a soldering iron to detach damaged components before securing new ones by ensuring proper attachment.

Step 8: Reassemble the Oven

After finishing repairs you should put the oven back together while making sure all wiring and components stay properly connected. Verify all connections before you shut the panel.

Step 9: Test the Oven

After plugging the oven in check that all its features work properly. Verify that the temperature remains steady while inspecting the display functionality and confirming proper oven cooking cycles. A successful oven operation indicates that the repair work is finished.

By following this procedure you can achieve an effective and complete commercial oven control board repair.

Check out this guide on how to replace your oven thermostat for a potential fix on temperature-related issues caused by a faulty thermostat.

When to Replace vs. Repair a Commercial Oven Control Board

The decision between replacement and repair of commercial oven control boards depends on both the severity of damage and the financial benefits of repair work. The following factors should be evaluated when deciding between replacement and repair of a commercial oven control board:

-

When to Repair: The control board qualifies for repair when its minor problems involve only a few defective components such as relays or capacitors. The cost of repairing a control board proves more economical than purchasing a new one when the damage affects specific areas of the board. The lifespan of an oven can be extended through control board repair when the board is new or the oven receives minimal usage.

-

When to Replace: The control board requires replacement when its extensive damage includes burnt areas and damaged circuitry or when it experiences frequent electrical failures. A control board that cannot be repaired will produce continuous oven performance problems which result in increased breakdown frequency. Replacement becomes the optimal choice for old or problematic ovens since ongoing maintenance proves unsustainable for long-term use.

Preventive Maintenance for a Commercial Oven Control Board

The lifespan of commercial oven control boards depends on preventive maintenance which also results in optimal performance. Commercial oven control boards maintain optimal functioning through scheduled maintenance because it prevents breakdowns and expenses on replacements. The following steps outline the procedure for commercial oven control board preventive maintenance:

-

Regular Cleaning: The control board accumulates grease moisture and dust during operation which eventually causes system malfunctions. A soft brush or compressed air system should be used periodically to clear debris from control boards during cleaning sessions. Liquid cleaners should be avoided because they can harm the components of the control board.

-

Check Wiring and Connections: Check all wiring connections to verify their secure attachment and absence of any damage. Damaged wires that become loose or frayed create power problems and break communication links between the control board and other oven components. Replace all damaged wiring immediately after tightening loose connections.

-

Monitor Power Surges: The control board will suffer damage when power surges occur. Placing your oven under the protection of surge suppressors helps defend its control board from dangerous electrical surge spikes. Paradigm owners need to verify that their surge protector continues working correctly through periodic checks.

-

Ensure Proper Ventilation: Excessive heat damages the control board to a severe extent. The oven requires sufficient ventilation and you should clean all air vents to prevent blockages. The control board stays protected from excessive heat during long periods of operation.

-

Regularly Test the Control Board: Regular testing of the control board will help verify its proper functioning. The testing process requires verification of temperature control systems alongside display operation and error code precision. Trouble identification at an early stage enables maintenance to take place before severe breakdowns occur.

Check out this ultimate guide on how to clean a Turbochef oven for more tips on maintaining your commercial oven to operate smoothly.

Commercial oven control board maintenance and repair work as essential elements to sustain smooth operation of your kitchen equipment. The ability to maintain commercial oven control boards depends on your knowledge of their function and your ability to detect problems and determine when to fix or replace them. The efficiency and longevity of control boards depend on performing regular preventive maintenance tasks which include cleaning operations and connection inspections as well as ventilator quality checks.

Early detection of non-functioning oven control boards enables you to prevent more serious issues from developing. Attending troubleshooting tasks requires very careful handling because you must first disconnect the power supply before checking all components. The decision to repair or replace the control board depends on how much damage exists and how old the oven is as well as the total cost-benefit analysis. Taking action to maintain your commercial oven enables you to lower costs while maintaining its efficient operation even after repairs have started.

FAQs

What should I do if my oven control board is not working?

If your oven control board is not working, check for power issues, such as a tripped breaker or blown fuse. Inspect for visible damage like burnt areas. If the problem persists, consult a technician to repair or replace the board.

How can I reduce the oven control board cost when replacing or repairing it?

To save the oven control board cost, try to repair the original board if only certain components such as relays or capacitors have failed. One can also shop around for prices from various sources or technicians. Choosing aftermarket or rebuilt parts can also reduce the overall price.

What causes the oven control panel not working?

The oven control panel not working can be caused by issues like a faulty control board, loose wiring, or a tripped circuit breaker. It can also result from a malfunctioning display or damaged touch sensors that prevent proper communication with the board.

How do I reset my oven control board?

To reset your oven control board, turn off the oven and unplug it for about 5-10 minutes. After plugging it back in, turn it on and check if the control panel and functions are restored. If the issue persists, further troubleshooting or professional repair may be needed.