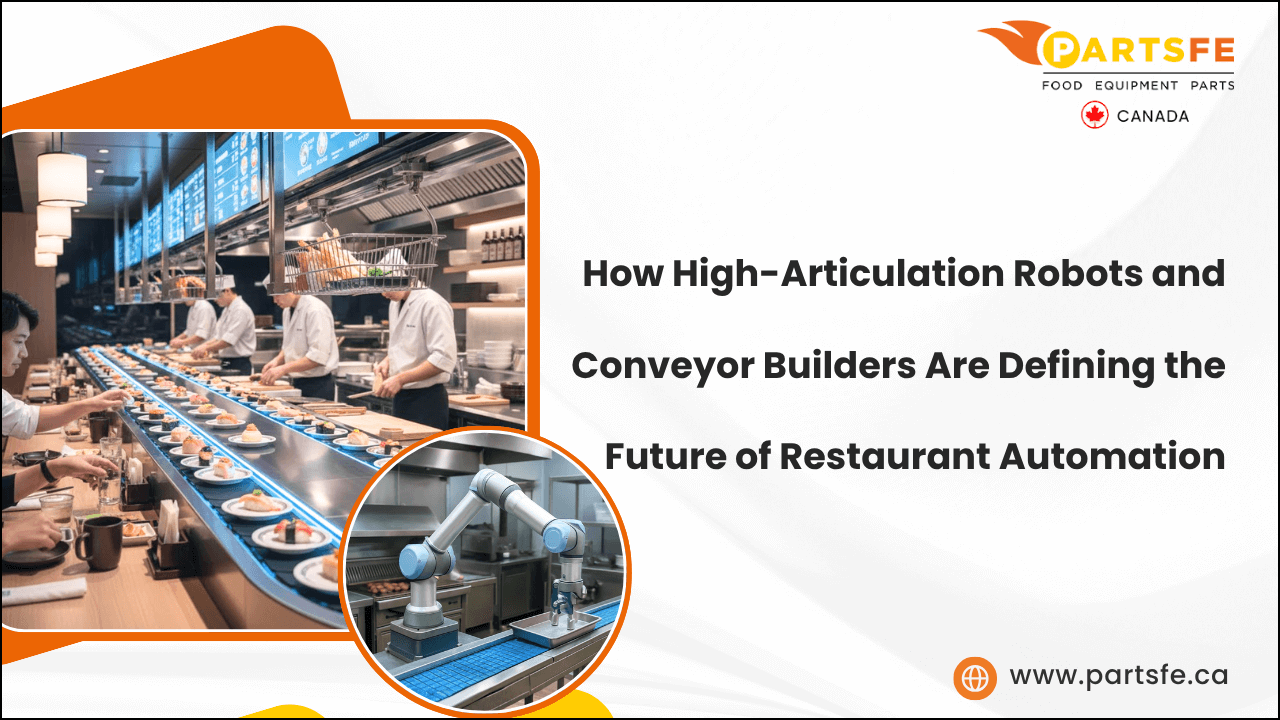

How High-Articulation Robots and Conveyor Builders Are Defining the Future of Restaurant Automation

The future of restaurant automation in Canada is being shaped by high-articulation robots and advanced conveyor systems. Canadian restaurants are increasingly adopting these technologies to meet growing customer demand for efficiency, consistency, and quality. High-articulation robots can perform complex cooking tasks with precision, from assembling poutine to preparing sushi, reducing labor pressures while maintaining consistent standards. At the same time, conveyor systems streamline kitchen operations, moving ingredients and finished dishes efficiently, even in busy urban restaurants in cities like Toronto, Vancouver, and Montreal.

By integrating robotic precision with automated logistics, Canadian eateries can serve meals faster, maintain strict hygiene standards, and adapt to the expectations of a tech-savvy dining public. This shift signals a new era where automation is central to the Canadian culinary experience.

How High‑Articulation Robots Are Transforming Canadian Kitchens

High‑articulation robots are reshaping Canadian kitchens, helping restaurants improve efficiency, quality, and customer experience. Their impact is most visible in busy urban markets and chains across Toronto, Vancouver, and Montreal. Key transformations include:

-

Automated Poutine Assembly: Robots are now capable of assembling iconic Canadian dishes like poutine, performing multiple steps with speed and accuracy. This automation reduces wait times and ensures consistent quality in fast-casual environments.

-

Sushi and Fusion Roll Precision: High-articulation robots are increasingly used in Japanese and fusion restaurants to maintain uniform roll sizes and presentation. They reduce human error and keep plating standards high even during peak hours.

-

Dessert Crafting for Bakeries: Robotic systems in bakeries help with repetitive and delicate tasks like icing, layering, and decoration. This improves consistency, reduces labor costs, and saves time for staff.

-

Allergen Management: Robots can be programmed to handle allergen-specific ingredients separately, helping prevent cross-contamination in kitchens. This supports strict food safety standards and improves customer confidence.

-

High-Volume Efficiency: Robots allow chains to scale production efficiently during peak hours without hiring additional staff. They ensure that customer demand is met without compromising quality.

By combining speed, precision, and safety, high-articulation robots are redefining what Canadian kitchens can achieve.

The Role of Conveyor Systems in Streamlining Canadian Restaurants

Conveyor systems are no longer just a novelty; they are addressing key operational challenges in Canadian kitchens. Beyond increasing speed, they are being used in innovative ways to improve safety, hygiene, and overall customer experience.

-

Temperature-Controlled Conveyors: Conveyors with chilled or heated zones maintain ingredient freshness and optimal serving temperature from prep to plate.

Application: Chilled sections keep raw ingredients fresh while heated zones maintain hot foods, ensuring dishes reach the customer at the perfect temperature during busy service hours. -

Integrated Waste Management: Some systems separate food scraps and waste from prep stations automatically, reducing labor and improving sanitation.

Application: Waste and scraps are automatically routed away from prep areas, minimizing staff handling, maintaining cleanliness, and improving workflow efficiency. -

Real-Time Inventory Tracking: Sensors on conveyors monitor ingredient usage as items move through the kitchen, helping maintain stock levels efficiently.

Application: Conveyor sensors track ingredient consumption in real-time, alerting staff when supplies are low and reducing waste while optimizing kitchen inventory. -

Multi-Station Synchronization: Conveyors coordinate multiple prep and plating stations, ensuring complex dishes are assembled smoothly and consistently.

Application: Conveyor systems time and coordinate multiple stations so that ingredients and components come together accurately, reducing delays and maintaining consistent quality. -

Contactless Table Delivery: Conveyor systems can deliver food directly to tables, reducing human contact and improving speed during peak hours.

Application: Automated delivery ensures dishes reach tables quickly and safely, improving service efficiency and reducing the risk of cross-contamination. -

Modular Design for Flexibility: Reconfigurable conveyors allow kitchens to adapt to menu changes or peak demand without costly renovations.

Application: Modular conveyor layouts can be quickly adjusted to accommodate seasonal menus or high-volume periods, keeping operations efficient without major redesigns.

By integrating conveyor systems, Canadian restaurants can streamline operations, improve efficiency, and enhance the overall dining experience.

Check out the commercial restaurant kitchen cleaning: daily, weekly, and monthly practices to maintain hygiene, safety, and operational efficiency.

Automation Meets Culinary Excellence: Canada’s Tech-Driven Dining Future

Canada’s restaurant industry is entering a new era where automation works alongside chefs to elevate culinary quality while improving operational efficiency.

-

Precision Flame-Grilling: Automated grills in commercial kitchens cook large volumes of proteins consistently, ensuring every steak, burger, or poultry item meets exact doneness and presentation standards.

-

AI-Driven Menu and Workflow Optimization: Artificial intelligence forecasts ingredient demand, minimizes waste, and optimizes workflow, allowing commercial kitchens to scale production while maintaining quality.

-

Robotic Delivery and Table-Tracking Systems: In large-scale facilities, service robots handle tray or plate delivery, improving accuracy, reducing bottlenecks, and enhancing operational flow.

-

Automated Quality Inspection and Portion Control: Cameras and sensors integrated into prep and cooking stations check portion sizes, plating accuracy, and ingredient quality, ensuring every dish meets the same high standard.

-

Automated Multi-Step Cooking and Recipe Execution: Robotics can follow complex recipes step by step, from combining ingredients to cooking and garnishing, guaranteeing consistency and freeing chefs for creative work.

-

Food-Safe, Low-Maintenance Robotics: FDA-compliant robotic components ensure automation equipment in commercial kitchens meets strict hygiene standards while remaining durable under heavy use.

-

24/7 Autonomous Cooking Systems: Robotic kitchens like RoWok™ operate continuously, enabling large institutions or catering operations to provide consistent meals even during off-peak hours.

Automation in commercial kitchens allows foodservice operators to maintain culinary excellence at scale, improving consistency, safety, and overall efficiency while supporting high-volume production.

Robotics and Efficiency: Meeting Canada’s Restaurant Challenges

Canadian restaurants face mounting pressures from labor shortages and rising operational costs. Robotics is helping operators improve efficiency, maintain consistency, and meet growing customer demand.

|

Section |

Function |

Challenges |

Solutions |

|

High-Articulation Robots in Restaurants |

Multi-joint robotic arms that perform cooking, plating, prep, and assembly tasks with high precision and consistency. |

High capital expense- Potential downtime- Integration complexity- Need for technically trained staff |

Start with modular robotic units- Implement preventive maintenance schedules- Choose plug-and-play robot systems- Provide progressive technical training |

|

Conveyor Builders in Restaurants |

Conveyor lanes transport ingredients and dishes through preparation, cooking, assembly, and delivery stages; often paired with sensors and AI. |

Requires layout redesign- Mechanical wear and upkeep- Staff unfamiliarity- Retrofitting challenges |

Use compact, scalable conveyor layouts- Perform routine mechanical inspections- Offer training on conveyor handling- Begin with partial retrofits before full deployment |

|

Robots + Conveyors: Synergy |

Robots assemble food while conveyors move dishes along the workflow, enabling smooth end-to-end automation from order to output. |

System disruption if one component fails- Complex timing and communication between systems |

Add redundant conveyor lanes or standby units- Use centralized automation controllers- Run simulation tests to identify bottlenecks |

|

Implementation Strategies for Automation |

Practical, step-by-step approaches that help restaurants adopt robotic and conveyor systems efficiently and cost-effectively. |

Operational disruption during setup- ROI uncertainty- Staff resistance to new technology |

Begin with small pilot automation projects- Use ROI monitoring tools- Provide workshops to support staff adoption |

Technologies Driving Restaurant Automation

While automation promises efficiency and consistency, there are nuanced challenges that restaurant operators rarely anticipate. Understanding these is critical to avoid surprises and ensure long-term success.

Automated Bowl-Preparation Systems:

These systems are engineered to assemble bowls at high volume, often handling hundreds of servings per hour. They consist of ingredient dispensers, portioning mechanisms, and conveyor or track systems that transport bowls from station to station.

-

Core Components: Portioning dispensers, robotic arms, conveyor belts, weighing sensors, and ingredient storage bins.

-

Functionality: Automatically adds proteins, grains, vegetables, and sauces in precise amounts according to pre-programmed recipes.

-

Benefits: Ensures consistent portion sizes, minimizes human error, and allows for high-volume production with minimal labor input.

Robotic Burger-Flipping Technology:

These systems automate the repetitive tasks involved in grilling proteins, especially burgers. They use robotic arms with end-effectors designed to handle heat, flip patties, and monitor cooking times.

-

Core Components: Multi-axis robotic arms, heat-resistant grippers, thermal sensors, integrated cameras, and cooking surface adapters.

-

Functionality: Tracks each item on the grill, flips or rotates them at precise intervals, and signals when items are cooked to specification.

-

Benefits: Reduces exposure to hot surfaces, ensures uniform cooking, and increases throughput during peak demand periods.

Robotic Fry-Station Systems:

These robots manage deep-frying tasks, handling items like fries, onion rings, and other fried foods. The systems are designed to safely and consistently operate fryers with minimal human intervention.

-

Core Components: Robotic arms with heat-tolerant grippers, frying baskets, temperature and timer sensors, and safety enclosures.

-

Functionality: Picks up food items, lowers them into hot oil, monitors cook times, and retrieves them automatically.

-

Benefits: Maintains consistent frying quality, improves kitchen safety, and reduces labor demands for high-risk cooking tasks.

High-Articulation / Humanoid Robotics:

These advanced robotic systems replicate fine-motor skills, enabling them to perform precise and complex tasks similar to human chefs. They often feature multiple joints and dexterous manipulators.

-

Core Components: Multi-axis robotic arms, force and torque sensors, grippers or adaptive end-effectors, AI control systems, vision-guided positioning systems.

-

Functionality: Performs intricate tasks like stirring, plating, ingredient assembly, or detailed food manipulation.

-

Benefits: Allows automation of delicate culinary processes, supports allergen management by separating ingredient handling, and improves plating consistency.

Conveyor-Based or Automated Makeline Builders:

These systems integrate robotics with conveyor belts to optimize kitchen workflow. They are designed to move dishes or components through prep, assembly, and finishing stages efficiently.

-

Core Components: Modular conveyors, robotic dispensers, sensor arrays, sorting mechanisms, portioning devices, and automated lifts.

-

Functionality: Orders or ingredients move along the conveyor; at each station, robotic devices or dispensers add components in precise sequences.

-

Benefits: Streamlines kitchen operations, reduces manual handling, allows for scalable high-volume production, and enables modular reconfiguration for menu or workflow changes.

Explore how to overcome the most common restaurant issues with practical solutions and expert insights for smoother operations and improved profitability.

The Future of Restaurant Automation: What’s Next for Canadian Kitchens

The future of restaurant automation in Canada promises kitchens that are faster, safer, and more precise than ever before. High-articulation robots, smart conveyors, and AI-driven systems will work together to streamline operations while enhancing culinary creativity. As technology continues to evolve, Canadian restaurants will redefine efficiency, consistency, and the overall dining experience for customers.

Key Takeaways:

-

Adaptive Meal Personalization at Scale: Automation allows restaurants to offer highly customized meals without slowing production, even during peak hours.

-

Real-Time Ingredient Intelligence: Smart sensors and robotic systems track usage and spoilage, enabling proactive inventory and waste reduction.

-

Cross-Station Workflow Synergy: Coordinated robots and conveyors reduce bottlenecks, ensuring multi-component dishes are prepared seamlessly.

-

Culinary Consistency Meets Creativity: High-articulation robots handle complex tasks, freeing human chefs to focus on innovative menu items.

-

Predictive Operations: AI-driven systems anticipate order surges, optimizing cooking and assembly before demand spikes.

Restaurant automation in Canada is not just about replacing labor—it’s about creating smarter, faster, and more precise kitchens. By combining robotics, conveyors, and AI, eateries can deliver consistent quality, reduce waste, and redefine the customer dining experience.

Looking for high-quality parts to keep your commercial kitchen equipment running flawlessly? PartsFe CA offers essential replacement components like thermopile sensors, heating elements, and control knobs, from leading brands such as Imperial, Frymaster, and Rational, to minimize downtime, maintain system accuracy, and ensure your equipment operates at peak performance.

References:

https://restaurant.org/education-and-resources/resource-library/make-room-for-restaurant-automation/

https://micsymposium.org/mics2023/wp-content/uploads/2023/03/MICS_2023_paper_5914.pdf

FAQs

How much does it cost to install high-articulation robots and conveyors in a restaurant?

High-articulation robots typically range from $30,000 to $150,000, depending on features and tooling. Conveyor systems vary by length and complexity, with additional costs for installation and calibration.

How scalable is this automation for small vs. large restaurant chains?

Large chains benefit most, as costs are spread across multiple locations and consistency is critical. Small restaurants can adopt modular setups, but ROI depends on volume and labor savings.

How long does it take to get a return on investment (ROI)?

The ROI for robotic food-prep systems is usually around 12–18 months. It depends on labor savings, increased throughput, and reduced food waste.

Why do some restaurants worry about the cost of maintenance?

Robots require regular maintenance, software updates, and occasional hardware repairs. Electricity usage and potential downtime can also add to operating costs.