How to Diagnose and Fix Commercial Grill Flame Sensor Issues Fast

A malfunctioning flame sensor in a commercial grill can disrupt kitchen operations and compromise safety. This small but vital component detects whether the burner flame is present, preventing gas leaks and ensuring consistent cooking performance. When it fails, the grill may shut off unexpectedly or fail to ignite altogether.

To diagnose flame sensor issues quickly, start by checking for dirt, grease, or carbon buildup on the sensor rod these can block flame detection. Clean it gently with fine sandpaper or a soft cloth. If cleaning doesn’t work, test for electrical continuity or replace the flame sensor if it’s corroded or cracked. Regular maintenance and timely replacement can restore efficiency and keep your grill running smoothly during peak business hours.

Understanding the Role of a Flame Sensor in Commercial Grills

The commercial grill flame sensor is a vital safety and performance component that ensures reliable operation in high-demand kitchens. Here are the key roles it plays:

-

Detects Flame Presence: Confirms whether the burner flame is active, ensuring gas only flows when ignition occurs.

-

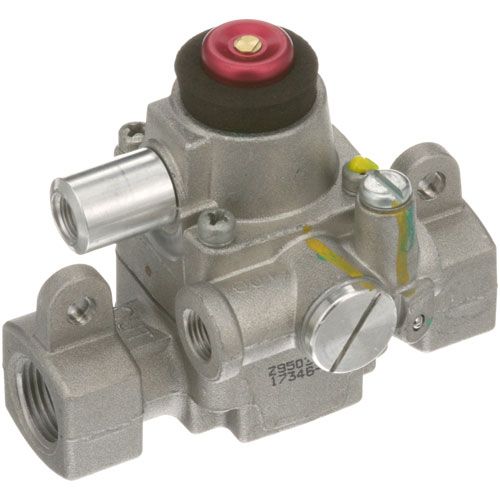

Prevents Gas Leaks: Shuts off the gas supply immediately if the flame goes out, avoiding dangerous gas buildup.

-

Maintains Temperature Consistency: Helps regulate the burner’s operation, ensuring even heat distribution and consistent cooking results.

-

Protects the Grill System: Prevents overheating or malfunction by stopping unburned gas from accumulating in the combustion area.

-

Improves Operational Safety: Acts as a safeguard against potential fires or explosions, keeping staff and equipment safe.

-

Enhances Energy Efficiency: Reduces fuel waste by ensuring gas is used only when the flame is properly detected.

-

Supports Automatic Ignition Systems: Works with the grill’s control board to enable automatic restarts when a flame is lost.

-

Indicates Maintenance Needs: Frequent flame failure signals may point to dirty burners or sensor issues, helping schedule timely maintenance.

These roles make the flame sensor essential for both safety and optimal performance in commercial grilling operations.

Looking for reliable replacement parts for commercial grills? PartsFe CA has you covered with top-quality components such as flame sensors, ignition modules, and burner assemblies from trusted brands like Vulcan, Hart, Blodgett, Garland, and Pitco. Visit us today to find the perfect parts for your commercial grill and keep your kitchen running safely and efficiently!

Key Signs Your Commercial Grill Flame Sensor Is Malfunctioning

Beyond the usual indicators, there are several less obvious, unique signs that a flame sensor may be failing. These early-warning signals often go unnoticed but can impact grill performance and safety:

-

Excessive Clicking of Igniters: The ignition keeps sparking repeatedly because the sensor fails to detect a flame.

-

Flame Flickering Without Reason: The burner flame appears unstable even when the gas flow is normal.

-

Grill Temperature Fluctuations: Heat rises and drops unexpectedly despite consistent settings.

-

Delayed Gas Shutoff: Gas continues flowing briefly after the flame goes out due to slow sensor response.

-

Sensor Heating Up Abnormally: The flame sensor becomes unusually hot, indicating an internal malfunction.

-

Intermittent Control Board Communication: The sensor sends inconsistent signals, triggering random shutdowns or error codes.

Recognizing these unique signs early allows for preventative cleaning, testing, or replacement of the flame sensor, keeping your commercial grill safe, efficient, and reliable.

Common Causes Behind Flame Sensor Problems in Commercial Grills

Some flame sensor issues stem from less obvious, unique causes that are often overlooked but can significantly impact grill performance and safety:

-

Vibrations from Heavy Usage: Continuous operation in busy kitchens can loosen connections or misalign the sensor over time.

-

Excessive Moisture or Steam: High humidity or steam from nearby cooking can cause sensor corrosion or false flame readings.

-

Electromagnetic Interference: Nearby electrical equipment can interfere with the sensor signal, triggering shutdowns.

-

Incorrect Sensor Replacement: Using a non-compatible sensor can lead to misreading the flame or frequent errors.

-

Burner Flame Shape Changes: Uneven or flickering flames due to clogged burners can prevent consistent detection by the sensor.

-

Accumulated Residual Heat: Residual heat from repeated cycles can overheat the sensor, affecting its sensitivity and longevity.

Identifying these unique causes helps operators take quick corrective action, keeping the flame sensor reliable. This ensures the grill runs safely and efficiently.

How to Diagnose Commercial Grill Flame Sensor Issues Step-by-Step

Proper commercial grill flame sensors troubleshooting helps identify ignition problems before they disrupt operations. Follow this step-by-step guide to diagnose issues accurately and restore efficient grill performance.

Excessive Igniter Clicking

Ignition keeps sparking even though the burner is lit.

-

Cause: Sensor fails to detect flame due to buildup or misalignment.

-

Symptoms: Continuous clicking, grill struggles to maintain flame.

-

Fix: Clean the sensor and remove any buildup. Reposition it properly near the flame for accurate detection. If the issue continues, refer to a commercial grill flame sensors troubleshooting manual for detailed calibration steps.

Flame Flickering Despite Clean Burners

Flame fluctuates even when burners are clean and gas is stable.

-

Cause: Loose wiring or improper sensor positioning.

-

Symptoms: Unstable flame, uneven heat output.

-

Fix: Check wiring connections and tighten any loose wires. Adjust the sensor position to ensure consistent flame detection.

Delayed Gas Shutoff After Flame Out

Gas continues to flow briefly after the flame goes out.

-

Cause: Slow-reacting sensor or internal degradation.

-

Symptoms: Gas odor or lingering flame after shutdown.

-

Fix: Test the sensor’s response time and replace if it reacts too slowly. Ensure proper installation to prevent future delays. If your commercial grill flame sensors not working even after testing, consider replacing it for reliability.

Sensor Overheating

Sensor becomes unusually hot or discolored due to repeated cycles or high heat exposure.

-

Cause: Prolonged exposure to high heat or repeated ignition cycles.

-

Symptoms: Visible discoloration, grill shutdowns, or sensor warping.

-

Fix: Move the sensor away from extreme heat zones. Perform a grill flame sensor replacement if the unit shows permanent damage.

Inconsistent Control Board Communication

Sensor sends irregular signals to the grill’s control board.

-

Cause: Damaged sensor or poor electrical connections.

-

Symptoms: Random shutdowns or intermittent flame errors.

-

Fix: Test the sensor with a multimeter for continuity. Replace it if the signals are irregular or weak.

Sensitivity to Steam or Humidity

Sensor malfunctions in high-moisture environments, causing false flame failures.

-

Cause: High moisture exposure affecting sensor readings.

-

Symptoms: Frequent shutdowns near steam or wet areas.

-

Fix: Reposition the sensor away from steam sources. Clean it thoroughly to restore proper detection. If performance doesn’t improve, the grill flame sensor is bad and needs replacement.

Check out this guide on how to replace commercial grill hood filters to maintain optimal airflow, improve kitchen safety, and enhance grill efficiency.

Effective Fixes and Replacement Tips for Faulty Flame Sensors

Ensuring a fully functional flame sensor is critical for safe and efficient operation of commercial grills. Here are effective fixes and replacement strategies:

Checking Wiring and Connections

-

Inspect all wiring connections to the control board for looseness.

-

Look for corrosion or rust on connectors and clean or replace as needed.

-

Test continuity with a multimeter to detect hidden wiring faults.

-

Secure wires with heat-resistant cable ties to prevent vibration-induced disconnections.

Proper Positioning and Shielding

-

Ensure the sensor is correctly aligned in the flame path.

-

Position the sensor in a stable flame zone without touching burners.

-

Add a small heat shield if the sensor is exposed to excessive radiant heat, which can cause overheating.

-

Keep the sensor away from steam, grease splash zones, or high-moisture areas.

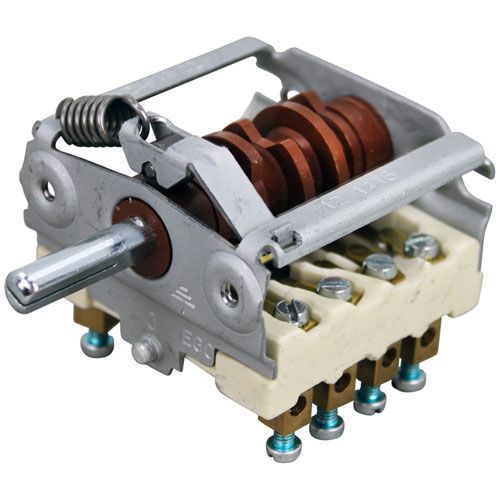

Replacement Tips

-

Use a high-quality OEM sensor compatible with your grill model.

-

Check for sensor models with built-in anti-corrosion coatings for longer life in humid environments.

-

Test the grill for consistent ignition and stable flame performance after replacement.

-

Record the installation date and schedule a sensor inspection every 6–12 months for high-traffic kitchens.

Check out this step-by-step guide on how to reset grill pressure regulators to restore proper gas flow and ensure safe, consistent grill performance.

Preventive Maintenance to Extend Flame Sensor Lifespan

Proactive maintenance of a commercial grill’s flame sensor prevents unexpected shutdowns, ensures safety, and extends sensor life. Implementing a structured schedule makes inspections and upkeep more effective.

Weekly Checks

-

Run ignition cycles without food to monitor flame stability.

-

Observe sensor response under low-stress conditions to catch early malfunctions.

-

Wipe away light grease or dust from the sensor rod to prevent minor buildup.

Monthly Maintenance

-

Inspect the sensor rod alignment and reposition it if vibrations or impacts have shifted it.

-

Test wiring connections for corrosion, looseness, or wear; tighten or replace as needed.

-

Apply light anti-corrosion spray to connectors in humid kitchens.

Seasonal Maintenance

-

Install or check protective heat shields around the sensor to prevent overheating from nearby burners.

-

Reposition sensors away from steam vents or wet areas and install drip shields if necessary.

-

For multi-burner grills, rotate sensor inspections between burners to detect uneven wear.

-

Consider using thermal paste on the sensor base (if compatible) to improve heat dispersion and reduce stress.

Performance Logging

-

Record sensor performance metrics during each inspection.

-

Track trends over time to identify declining efficiency before failure.

A structured weekly, monthly, and seasonal maintenance schedule greatly reduces flame sensor failures It also boosts reliability and extends the sensor’s lifespan in busy commercial kitchens.

Wrapping Up: Ensuring Reliable and Safe Commercial Grill Performance

Commercial grill flame sensors may be small, but they play a critical role in maintaining safety, consistent cooking, and overall kitchen efficiency. Ignoring early warning signs can lead to unexpected shutdowns, uneven heat, or even hazardous gas leaks.

Key Takeaways:

-

Flame sensors detect flame presence and prevent gas leaks, ensuring staff and kitchen safety.

-

Unique issues like sensitivity to moisture, vibrations, or inconsistent control board signals can affect grill performance.

-

Early detection of sensor problems through inspection or testing reduces downtime and prevents costly repairs.

-

Replacing faulty sensors with high-quality, compatible components ensures reliable ignition and stable flame operation.

Summary: Understanding your flame sensor’s role, recognizing early signs of malfunction, and taking corrective action keeps your commercial grill running efficiently and safely. By staying vigilant to sensor performance, operators can optimize energy use, maintain consistent cooking results, and ensure uninterrupted operation during peak business hours.

FAQs

Why does my furnace flame sensor fail repeatedly, and how can I reset it properly?

Turn off the furnace power, remove the flame sensor, clean it gently with fine sandpaper, reinstall it, and restart the system to reset.

How do I fix a low flame on a gas grill?

Check and clean the burner ports, ensure the propane tank is full, and reset the regulator to restore proper gas flow and flame height.

Why does my grill flame keep going out?

Your grill flame may go out due to low gas pressure, clogged burners, or a faulty flame sensor. Clean the burners and check the regulator for proper flow.

Why is my grill regulator not letting gas through?

A tripped safety mechanism or blocked regulator can stop gas flow. Reset the regulator and ensure the propane tank valve is fully open.

How to unclog burners on a gas grill?

Remove the grates and burner tubes, then use a small wire brush or toothpick to clear debris from the ports. Reassemble and test for even flame distribution.