Hoshizaki Ice Machine Cleaning and Maintenance A Complete Step-by-Step Guide

Commercial ice machines are essential in restaurants, hotels, healthcare facilities, and foodservice operations. Among the most trusted brands, Hoshizaki ice machines are known for durability, clear ice production, and consistent performance. However, without proper care, even reliable machines can suffer from reduced efficiency and premature failure.

This guide covers Hoshizaki ice machine cleaning, preventive maintenance best practices, common cleaning mistakes, and a step-by-step process to keep your unit sanitary, efficient, and health-code compliant, helping operators maintain peak performance and long-term reliability.

Why Regular Cleaning and Maintenance Is Critical for Hoshizaki Ice Machines

Ice is considered a food product. That means any contamination inside an ice maker directly affects food safety and customer health. Over time, mineral scale, slime, mold, and bacteria accumulate inside water lines, evaporator plates, bins, and other ice machine parts.

Key reasons routine cleaning is essential

1. Food safety and health compliance: Ice is a consumable product, making ice machines a priority for health inspectors. Regulations require regular cleaning and sanitizing to prevent bacterial growth. Skipping maintenance can result in failed inspections, fines, or shutdowns. Routine cleaning keeps your Hoshizaki ice machine safe and compliant.

2. Ice quality and taste: Mineral scale and biofilm cause cloudy ice, bad odors, and off-tastes. These are early signs of poor sanitation. Proper cleaning a Hoshizaki ice machine removes buildup, restoring clear, odor-free ice—essential for bars, hotels, and healthcare facilities.

3. Equipment efficiency: Dirty evaporators and restricted water flow force the machine to work harder, reducing ice production and increasing energy use. Regular cleaning maintains proper heat transfer and water flow for consistent, efficient operation.

4. Longer equipment lifespan: Routine maintenance critical Hoshizaki ice machine parts such as pumps, valves, sensors, and evaporators. Removing scale and debris reduces wear, extends equipment life, and lowers long-term repair costs.

5. Reduced downtime and repair costs: Preventive cleaning helps identify minor issues such as restricted water flow or early component wear before they become major failures. This minimizes unexpected breakdowns, emergency service calls, and costly repairs that disrupt daily operations.

In high-volume commercial settings, skipping scheduled Hoshizaki ice machine cleaning can shorten machine life by years, increase operating costs, and put food safety at risk. Regular cleaning and maintenance are not just best practices—they are essential for reliability, compliance, and profitability.

Looking for a dependable source of restaurant equipment parts online? Shop at PartsFe CA and keep your equipment performing at its best. At PartsFe CA, we simplify equipment maintenance by offering high-quality commercial kitchen and restaurant equipment parts built for durability and precise fit. From motors, switches, valves, and control components to refrigeration, beverage, and cooking equipment parts, with competitive pricing, fast shipping across Canada, and knowledgeable support.

Common Mistakes to Avoid When Cleaning a Hoshizaki Ice Machine

Even well-intentioned operators often make errors that reduce cleaning effectiveness or damage components.

1. Using the wrong cleaner: Household cleaners, bleach, or harsh chemicals can corrode surfaces and void warranties. Always use an approved Hoshizaki ice machine cleaner and compatible sanitizer.

2. Skipping the sanitize step: Descaling removes minerals, but sanitizing eliminates bacteria and mold. Both steps are mandatory.

3. Not disassembling removable parts: Curtains, bins, floats, and water distribution components must be removed and hand-cleaned. Running only a Hoshizaki ice machine clean cycle is not enough.

4. Infrequent cleaning schedules: Many operators clean only when ice quality drops. Hoshizaki recommends routine cleaning every 3–6 months, or more often in hard-water areas.

5. Ignoring the condenser: A dirty air-cooled condenser causes overheating and reduced ice production, even if internal components are clean.

Avoiding these mistakes ensures your Hoshizaki ice maker cleaning instructions deliver real results.

Check out Hoshizaki ice machine troubleshooting: a complete guide, which covers common issues, diagnostic steps, practical fixes, and preventive tips to restore performance and ensure reliable ice production.

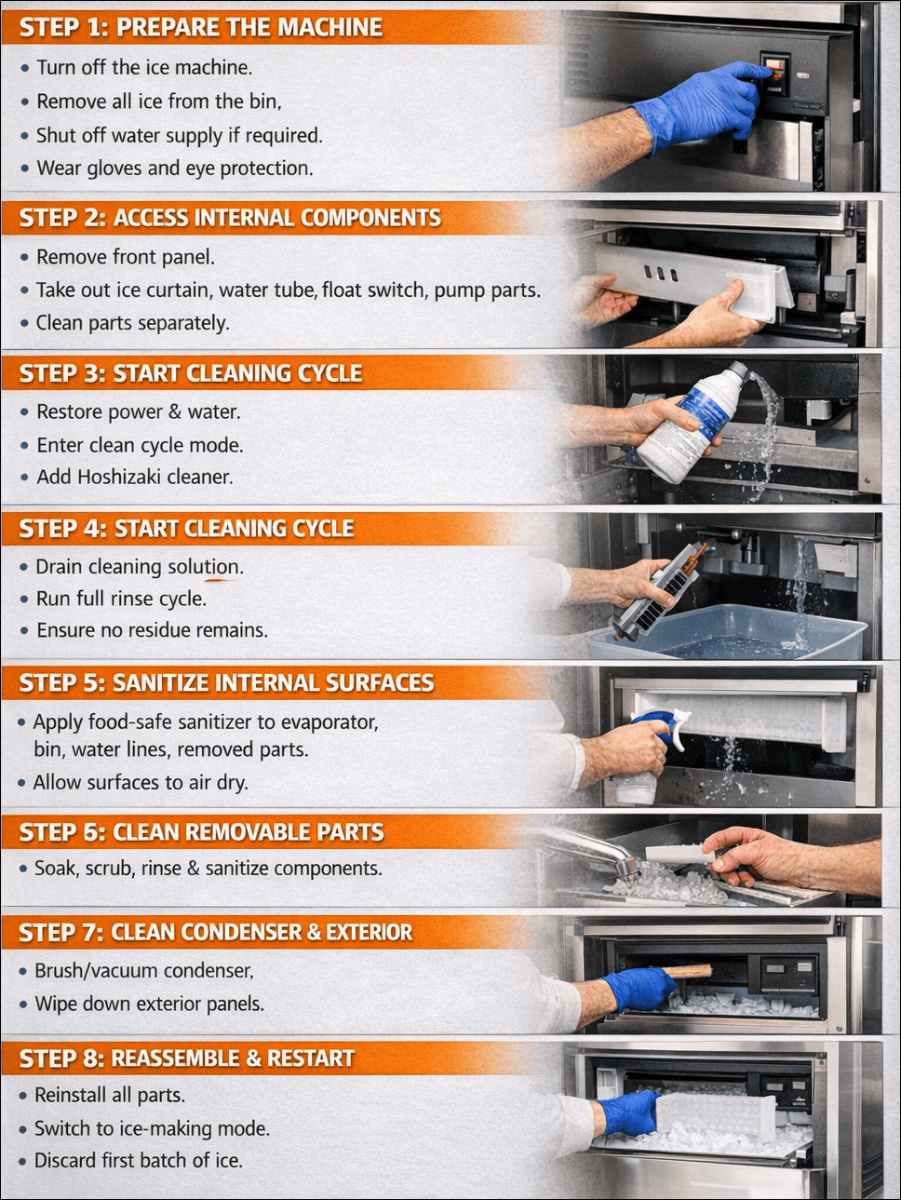

How to Clean Hoshizaki Ice Machines Step-by-Step

This section provides a professional, field-tested approach aligned with standard Hoshizaki ice machine cleaning manual guidelines. Always refer to your specific model documentation before starting.

| Caution: Before performing any cleaning or maintenance, disconnect the power and water supply to the ice machine. Wear appropriate personal protective equipment (PPE) when handling cleaners and sanitizers. Always follow model-specific instructions provided by Hoshizaki. Failure to follow proper safety procedures may result in injury, equipment damage, or voided warranties. |

Check out clean or replace ice machine: here’s everything you need to know, which helps you decide between cleaning or replacing your ice machine for optimal performance.

Preventive Maintenance Checklist for Long-Term Performance

Cleaning alone is not enough. Preventive maintenance protects critical systems and extends machine life.

|

Maintenance Frequency |

Task |

What to Check / Action |

Purpose |

|

Daily / Weekly |

Inspect ice quality |

Check ice clarity, odor, and taste |

Ensures food safety and consistent ice quality |

|

Check bin door seal |

Confirm the ice bin door seals properly |

Prevents contamination and temperature loss |

|

|

Verify water flow & drainage |

Ensure smooth water flow and proper draining |

Avoids clogs and overflow issues |

|

|

Monthly |

Inspect water filters |

Replace filters if clogged or restricted |

Maintains proper water quality and flow |

|

Check hoses & fittings |

Look for leaks or loose connections |

Prevents water damage and pressure loss |

|

|

Clean exterior vents |

Remove dust and debris from louvers |

Improves airflow and cooling efficiency |

|

|

Quarterly / Biannual |

Full machine cleaning |

Perform complete Hoshizaki ice machine cleaning. |

Removes scale, slime, and bacteria buildup |

|

Sanitize internal surfaces |

Clean ice bin and interior components |

Ensures hygienic ice production |

|

|

Inspect internal components |

Check pump, float switch, and valves |

Prevents unexpected mechanical failures |

|

|

Assess critical parts |

Inspect key Hoshizaki Ice Machine parts |

Identifies wear before breakdown occurs |

|

|

Annual (Professional Service) |

Full system inspection |

Schedule technician-led inspection |

Detects hidden or developing issues |

|

Electrical & refrigeration check |

Evaluate electrical and cooling systems |

Ensures safe and efficient operation |

|

|

Performance testing |

Calibrate machine and test ice output |

Confirms peak performance and capacity |

|

Disclaimer: The preventive maintenance checklist is intended for operational reference only. Certain tasks—especially electrical, refrigeration, and internal component inspections—should be performed by licensed or factory-authorized technicians. Maintenance requirements may vary based on local health codes, water conditions, and specific Hoshizaki ice machine models. |

When to Schedule Professional Service for Your Hoshizaki Ice Machine

Professional service should be scheduled if ice production drops, unusual noises occur, leaks are detected, error codes appear, or the unit fails a routine inspection. Even without visible issues, annual professional servicing helps identify hidden problems early and ensures the machine operates safely, efficiently, and in compliance with health standards.

A documented maintenance schedule reduces unexpected failures and keeps your ice machine operating at peak efficiency year-round.

Summary: Keep Your Hoshizaki Ice Machine Clean, Efficient, and Reliable

Maintaining a Hoshizaki ice machine requires more than occasional cleaning—it demands a consistent, structured maintenance approach. By following proper Hoshizaki ice machine cleaning procedures, using approved cleaning solutions, and adhering to recommended Hoshizaki ice maker cleaning instructions, operators can ensure food safety, optimal ice quality, and long-term equipment reliability. Regular preventive maintenance also protects critical ice machine parts, reduces unexpected failures, and helps businesses remain compliant with health regulations while controlling operating costs.

Key Takeaways:

-

Consistent cleaning and sanitizing routines are essential for safe, clear, and odor-free ice production.

-

Following manufacturer-recommended cleaning instructions helps prevent damage and maintain peak efficiency.

-

Proper care of critical ice machine parts extends equipment lifespan and reduces repair expenses.

-

Preventive maintenance minimizes downtime, emergency service calls, and operational disruptions.

-

A disciplined maintenance schedule protects your investment and ensures reliable ice production year after year.

Making cleaning and maintenance a routine priority keeps your Hoshizaki ice machine performing efficiently, safely, and dependably in any commercial environment.

FAQs

How to clean the Hoshizaki ice maker KM-151BAH?

Place the KM-151BAH into the clean cycle, add approved cleaner, run the cycle, rinse thoroughly, and then sanitize all internal surfaces and removable components before restarting.

How do I run a clean cycle on my Hoshizaki ice maker?

Move the control switch to CLEAN mode, add the recommended Hoshizaki ice machine cleaner, allow the cycle to complete, then perform a full rinse cycle.

Can I run vinegar through my Hoshizaki ice maker to clean it?

No. Vinegar is not recommended, as it can damage components and void warranties. Always use manufacturer-approved cleaners.

How do I clean the inside of my Hoshizaki ice maker?

Remove ice, disassemble removable parts, run the clean cycle with proper cleaner, rinse, sanitize all internal surfaces, and air dry before reassembly.