10 Common Commercial Dishwasher Timer Problems and How to Fix Them

A commercial dishwasher is essential for maintaining efficiency and hygiene in busy kitchens. However, when the timer malfunctions, it can disrupt the entire cleaning process, leading to delays and potential health risks. The timer controls each cycle's start and stop, so even a small issue can cause major problems.

In this article, we’ll explore 10 of the most common commercial dishwasher timer problems and provide clear, practical solutions to fix them. Whether you’re dealing with a cycle that won’t start, stops midway, or runs too long, understanding these issues can save you time and money. Keep your dishwasher running smoothly and avoid costly breakdowns with this easy-to-follow troubleshooting guide.

| Table of Contents: Understanding the Role of the Timer in Commercial Dishwashers 10 Common Timer Problems in Commercial Dishwashers How to Diagnose Commercial Dishwasher Timer Issues Effectively Preventive Maintenance Tips to Avoid Timer Problems in Your Commercial Dishwasher When to Repair vs Replace a Faulty Timer in Your Commercial Dishwasher Conclusion |

Understanding the Role of the Timer in Commercial Dishwashers

In a commercial dishwasher, the timer plays a key role in automating the cleaning process. It controls when each part of the wash cycle begins and ends, helping the machine run efficiently and deliver consistent cleaning results.

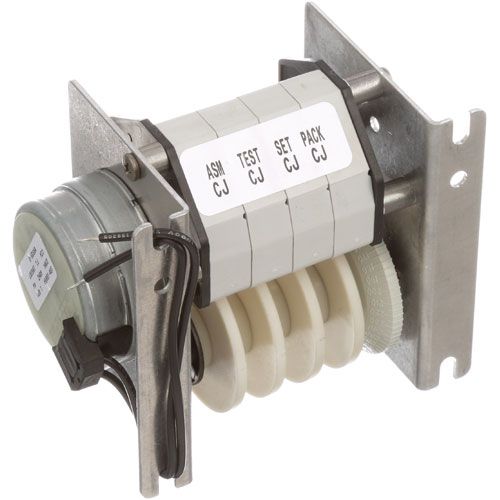

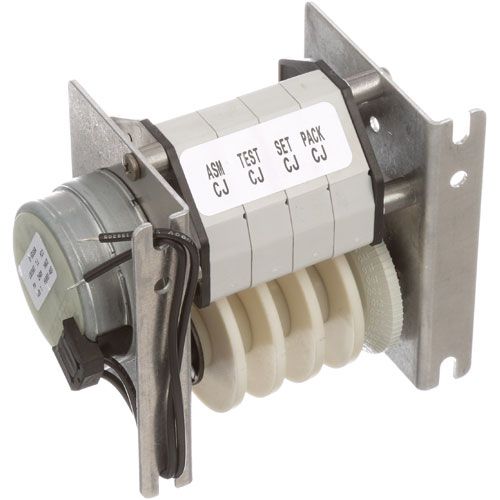

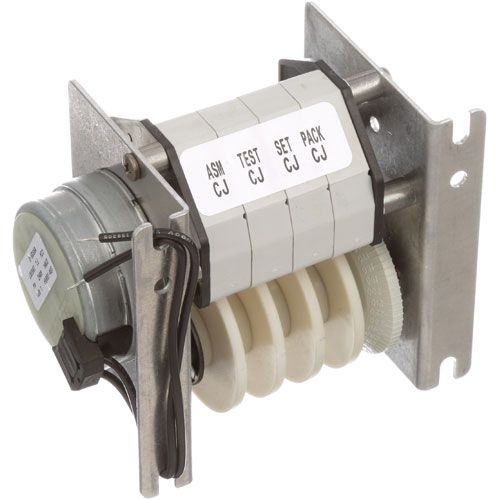

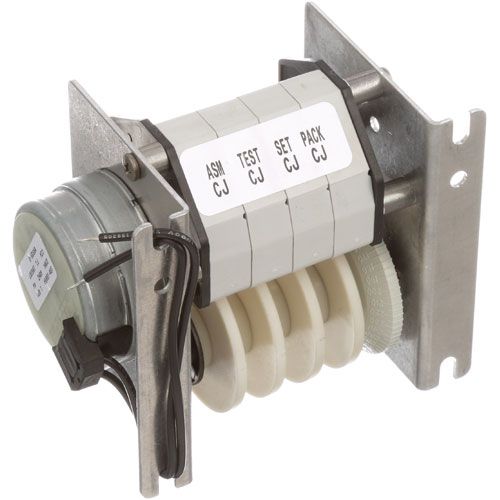

The mechanical vs electronic dishwasher timer affects performance and maintenance. Mechanical timers utilize gears, whereas electronic ones provide precise digital control.

Below are the main functions managed by the timer:

-

Water Intake: Controls how much water enters the machine and when the fill cycle starts.

-

Temperature Control: Activates the heating system to reach the proper water temperature for washing.

-

Wash Cycle Duration: Times how long the spray arms or jets clean the dishes.

-

Rinse Function: Initiates the rinse phase to clear off soap and debris.

-

Water Drainage: Operates the drainage system to empty dirty water after the cycle.

-

Drying (if included): Powers the fan or heating unit to dry dishes at the end of the cycle.

-

Switching Phases: Manages the smooth transition from one cycle phase to another.

-

Overall Timing: Ensures that each stage runs for the correct length of time.

By understanding how the timer coordinates each function, it becomes easier to spot issues and maintain the dishwasher’s performance.

Looking for the right parts to fix your commercial dishwasher timer? At PartsFeCA, we stock top replacements like timers, timer knobs, and timer relays from Blodgett, Cleveland, and Delfield to keep your equipment running smoothly.

10 Common Timer Problems in Commercial Dishwashers

Commercial dishwasher timers regulate each cleaning stage, ensuring efficient operation. Identifying common timer issues can save time and costly repairs.

Timer Not Advancing

If your dishwasher timer is not advancing through its cycles, it’s usually because:

-

The synchronous timer motor has failed

-

The cam gear is seized or stuck

To diagnose, test the timer coil for electrical continuity and inspect for heat discoloration, which can indicate motor burnout.

Dishwasher Stuck in One Cycle

When a commercial dishwasher is stuck on one cycle, such as wash or rinse, it may be due to:

-

Welded timer contacts

-

A misaligned (misindexed) cam that keeps the controller from advancing

Replacing the timer typically restores proper switch sequencing and cycle progression.

Intermittent Timer Operation

If the timer sometimes advances and sometimes pauses unexpectedly, this often points to:

-

Weak timer motor torque

-

Arcing contacts are causing unreliable switching under load

A good first step is to reseat the harness connections; if that doesn’t help, replacing the timer assembly is usually necessary.

Cycle Times Too Short or Too Long

When a commercial dishwasher cycle is too long or ends prematurely, it could be due to:

-

Using an incorrect timer variant (wrong seconds, cam count, or voltage), or

-

A misadjusted cam alters the programmed cycle durations.

Make sure to install the exact timer that matches your dishwasher’s timing specifications.

Burnt or Damaged Timer Motor

A burnt smell or visible discoloration on the timer motor typically indicates a dishwasher timer burned out due to:

-

Overheating caused by moisture ingress

-

Overvoltage conditions

-

A jammed gear train

In these cases, replacing the timer motor assembly is the safest course of action.

Timer Dial Hard to Turn or Stuck

If the timer dial is hard to turn on your dishwasher or feels stuck:

-

The bushings might be galled (worn and rough)

-

The cam pack could be binding internally

Avoid forcing the dial, as this can crack hubs or cause teeth to skip. Instead, replace the entire timer mechanism.

Timer Skipping Cycles

When your dishwasher timer is skipping cycles, like rinse or drain, it may be due to:

-

Worn cam lobes (raised portions on the cam that engage switches), or

-

Broken detents that fail to hold the timer in the correct position.

Replacing the cam timer assembly usually fixes the problem and restores normal stage progression.

Electrical Arcing or Sparking in the Timer

If you notice sparking or arcing inside the timer, this usually means:

-

The timer contacts have become carbonized

-

There is moisture or contamination inside the timer housing

Replace the timer and also check downstream components like pumps and heaters for faults to prevent the issue from returning.

Noisy Timer Operation

A dishwasher timer noise problem, such as grinding or clicking, can indicate:

-

Chipped or damaged gears

-

Failing bearings inside the timer

Proactive replacement is recommended to avoid a complete seizure and further damage.

Digital Timer Display Malfunctioning

When a digital timer malfunctions in a dishwasher occurs such as display issues, it’s often due to:

-

Low-voltage power feed

-

Failure of the keypad ribbon cable

-

Faults within the control/timer logic board

For electronic models, replacing the integrated control/timer module is usually necessary.

How to Diagnose Commercial Dishwasher Timer Issues Effectively

Commercial dishwasher timers are crucial for managing wash cycles and ensuring proper operation. This dishwasher timer troubleshooting guide helps quickly identify common issues, saving time and preventing costly downtime.

Timer Stuck in One Cycle

Issue: Dishwasher remains stuck in either the wash or rinse cycle and does not progress.

Cause: This issue is commonly caused by a misindexed timer cam in Garland units, or welded timer contacts in Pitco models.

Diagnosing Steps:

-

Inspect the timer cam mechanism for misalignment or damage.

-

Check timer contacts for welding or sticking.

-

Manually advance the timer to verify if it moves to the next cycle.

-

Test the timer motor operation using a multimeter.

Solution: Repair or replace the cam mechanism or timer contacts to restore normal cycle advancement. If the timer motor is faulty, replace the entire timer assembly.

Timer Malfunction Causing Overload

Issue: Dishwasher trips circuit breakers or emits a burnt smell near the timer.

Cause: This often results from timer motor failure, or internal timer short circuits, in Blodgett units and True units

Diagnosing Steps:

-

Visually inspect the timer motor and surrounding wiring for burns or damage.

-

Test the timer motor windings for shorts using a multimeter.

-

Check for abnormal current draw from the timer motor.

-

Inspect timer housing for signs of internal short circuits.

Solution: Replace any damaged wiring or timer motor components responsible for the overload. Ensure proper insulation and tight connections to prevent future faults.

Short Circuit in Timer Wiring

Issue: Dishwasher fails to start or behaves erratically (e.g., skips steps, random pauses).

Cause: Caused by connector wear in Hoshizaki models or wiring harness faults in Garland models.

Diagnosing Steps:

-

Examine wiring harnesses and connectors for corrosion or physical damage.

-

Use a continuity tester to check for short circuits between wires.

-

Perform a wiggle test while the unit is running to identify intermittent shorts.

-

Inspect the timer terminal block for loose or burnt connections.

Solution: Repair or replace damaged wiring harnesses and connectors. Tighten or replace faulty terminal block connections for consistent operation.

Timer Not Advancing Properly

Issue: Timer pauses or stops mid-cycle and fails to complete programmed cycles.

Cause: Often due to weak timer motors in Pitco units or seized cam gears in Blodgett units.

Diagnosing Steps:

-

Test the coil continuity of the timer motor using a multimeter.

-

Inspect cam gears and internal mechanical parts for signs of wear or binding.

-

Rotate the timer motor shaft manually to check for smooth operation.

-

Confirm that the voltage supply to the timer motor is correct and stable.

Solution: If you're wondering how to fix dishwasher timer motor issues, first check for continuity and mechanical binding. Replace worn parts and ensure stable voltage to prevent malfunctions.

Faulty Timer Contacts

Issue: Dishwasher operates intermittently or fails to complete cycles.

Cause: Caused by carbonized timer contacts in True units and pitted contacts in Hoshizaki units.

Diagnosing Steps:

-

Open the timer housing and inspect contacts for carbon buildup or pitting.

-

Test continuity across contacts at various timer positions using a multimeter.

-

Use contact cleaner to clean light carbon buildup.

Solution: Clean contacts if the buildup is minor. If the contacts are badly worn or pitted, replace the timer or associated relays. Perform regular maintenance to extend contact life.

Check out this guide on how to fix a commercial dishwasher discharge hose for quick steps to identify, repair, or replace a faulty hose efficiently.

Preventive Maintenance Tips to Avoid Timer Problems in Your Commercial Dishwasher

Routine maintenance is essential to keep your commercial dishwasher’s timer working reliably. Small, regular steps can prevent costly repairs and extend the timer’s lifespan.

-

Keep the Timer Clean: Remove dust and grease regularly to avoid timer jams. Use a soft brush or compressed air for gentle cleaning.

-

Check Electrical Connections: Inspect wiring often for damage or looseness. Tighten or replace faulty wires immediately.

-

Lubricate Moving Components: Apply manufacturer-recommended lubricant to timer gears. This reduces wear and ensures smooth operation.

-

Avoid Overloading the Dishwasher: Follow load capacity guidelines to prevent extra stress on parts. Overloading can damage the timer mechanism.

-

Maintain Stable Voltage Supply: Ensure the dishwasher gets consistent voltage to avoid electrical issues. Use surge protectors if necessary.

-

Arrange for Regular Professional Check-ups: Have a technician inspect the dishwasher periodically. Early detection prevents major timer failures.

Check out this guide on how to replace a commercial dishwasher water inlet valve to restore proper water flow and ensure efficient operation.

When to Repair vs Replace a Faulty Timer in Your Commercial Dishwasher

Faulty timer issues can disrupt your dishwasher’s operation and cause costly delays. Knowing when to repair or replace the timer helps maintain efficiency and reduce downtime.

|

Condition |

Repair |

Replace |

|

Contact Issues |

Clean or lightly gritty particle contacts |

Replace the timer if the contacts are badly damaged |

|

Minor Component Failure (e.g., relay) |

Replace the relay or small parts |

Replace the timer if multiple parts fail |

|

Timer Motor Failure |

Usually requires full replacement |

Replace the entire timer assembly |

|

Mechanical Damage (e.g., cam mechanism) |

Rarely repairable |

Replace the timer assembly |

|

Electrical Shorts Inside Timer |

Not repairable |

Replace the timer to avoid hazards |

|

Frequent Failures or Old Timer |

Temporary repair possible |

Replace to prevent future downtime |

Conclusion

Timer issues are a frequent cause of commercial dishwasher downtime but can often be prevented or fixed with timely diagnosis and maintenance. Understanding common problems from stuck cycles to electrical shorts helps technicians quickly identify and resolve issues, minimizing disruptions in busy kitchens.

Knowing when to repair or replace faulty timers based on the severity of the problem ensures cost-effective solutions and longer equipment life. Regular upkeep and brand-specific knowledge keep your dishwasher running efficiently, saving both time and money in the long run.

FAQs

Why is the timer not working on my dishwasher?

The timer may be faulty due to a worn motor, damaged cam, or burnt contacts. It can also fail if there's an electrical short or a problem with the control board.

What is the most common failure on a dishwasher?

One of the most common failures is a clogged or faulty drain pump. However, control issues like timer malfunctions are also frequent in commercial units.

How to tell if a dishwasher control board is bad?

If the dishwasher doesn’t respond, skips cycles, or behaves erratically, the control board may be failing. Burnt components or no LED activity are also signs.

Why won't my dishwasher timer advance?

A stuck or weak timer motor, seized cam, or power supply issue can prevent it from advancing. Mechanical binding or internal damage may also be to blame.