How to Troubleshoot Your Hamilton Beach FlexBrew Issues Like a Pro

In busy commercial and hospitality environments, the Hamilton Beach FlexBrew must operate reliably under constant use. When problems arise—such as inconsistent brewing, blinking lights, or water flow issues—productivity can quickly suffer. These common Hamilton Beach FlexBrew issues are frequent in high-use settings but are often easy to resolve with the right approach.

This guide offers practical Hamilton Beach coffee maker FlexBrew troubleshooting tips, helping technicians and facility managers quickly identify faults and use the right Hamilton Beach FlexBrew parts to restore smooth, efficient performance.

Understanding the Hamilton Beach FlexBrew in Commercial Environments

The Hamilton Beach FlexBrew is a versatile coffee system built for brewing both single-serve pods and ground coffee, making it ideal for shared commercial environments. In offices, cafés, hotels, and foodservice locations, FlexBrew machines often operate continuously, creating more mechanical and thermal stress than residential use.

This heavy workload strains internal components such as pumps, heating elements, valves, and sensors. Without regular cleaning and timely replacement of worn Hamilton Beach FlexBrew parts, performance declines, temperature becomes inconsistent, and operational errors increase. Routine inspection and care of Hamilton Beach FlexBrew coffee maker parts deliver several critical operational benefits:

-

Reliable Brewing Performance: Clean brew baskets, needles, and water lines ensure steady water flow, correct pressure, and consistent extraction throughout the day.

-

Reduced Equipment Downtime: Replacing worn seals, valves, and fittings before failure prevents unexpected breakdowns during peak usage hours.

-

Improved Energy Efficiency: Scale-free heating elements transfer heat more effectively, allowing the machine to reach brewing temperature faster and maintain it with less energy.

-

Lower Maintenance Costs: Using genuine Hamilton Beach FlexBrew coffee maker replacement parts protects compatibility and reduces repeat service calls caused by premature or improper part failures.

-

Extended Equipment Lifespan: Proactive maintenance slows wear on critical internal systems, helping the FlexBrew remain reliable in demanding commercial environments.

Understanding how the Hamilton Beach FlexBrew performs under commercial workloads reinforces that proper maintenance is not optional—it is a core operational requirement for consistency, efficiency, and long-term reliability.

Looking for a dependable source of restaurant equipment parts online? Shop at PartsFe CA and keep your equipment performing at its best. At PartsFe CA, we simplify equipment maintenance by supplying high-quality commercial kitchen & restaurant equipment parts engineered for durability and precise fit. From motors, switches, valves, and control components to refrigeration, beverage, and cooking equipment parts, we stock quality products that help reduce downtime and extend equipment lifespan. With competitive pricing, fast shipping across Canada, and knowledgeable support, PartsFe is your go-to source.

Common Hamilton Beach FlexBrew Problems in High-Use Settings

High-volume use accelerates wear and increases the likelihood of operational issues. Below are the most frequent Hamilton Beach FlexBrew issues encountered in commercial environments.

|

Problem |

Description / Symptoms |

Common Causes |

Impact if Ignored |

|

Hamilton FlexBrew Not Brewing |

The machine does not start brewing or stops mid-cycle |

Mineral scale buildup, clogged water lines, faulty lid sensors, and failing pump |

Complete brewing failure and service downtime |

|

Hamilton Beach FlexBrew Clogged Water System |

Slow or no water flow to the brew chamber |

Mineral deposits blocking internal tubing or brew needles, hard water usage |

Restricted water flow and poor coffee extraction |

|

Inconsistent Brew Temperature |

Coffee brews lukewarm or takes longer than normal |

Scale buildup on the heating element reduces heat transfer |

Poor beverage quality and increased energy usage |

|

Hamilton Beach FlexBrew Light Blinking |

The warning light remains on or flashes repeatedly |

Sensor errors, overheating, and incomplete brew cycles |

Frequent interruptions and false error alerts |

|

Frequent Need for Reset |

The machine requires repeated power resets to operate |

Debris buildup, internal scale, worn control components |

Accelerated component wear and unreliable operation |

|

Caution: Always disconnect power and allow the unit to cool completely before inspecting or servicing your Hamilton Beach FlexBrew. Components such as heating elements, pumps, and internal wiring may remain hot or energized after use. Failure to follow proper safety procedures can result in electric shock, burns, or equipment damage. |

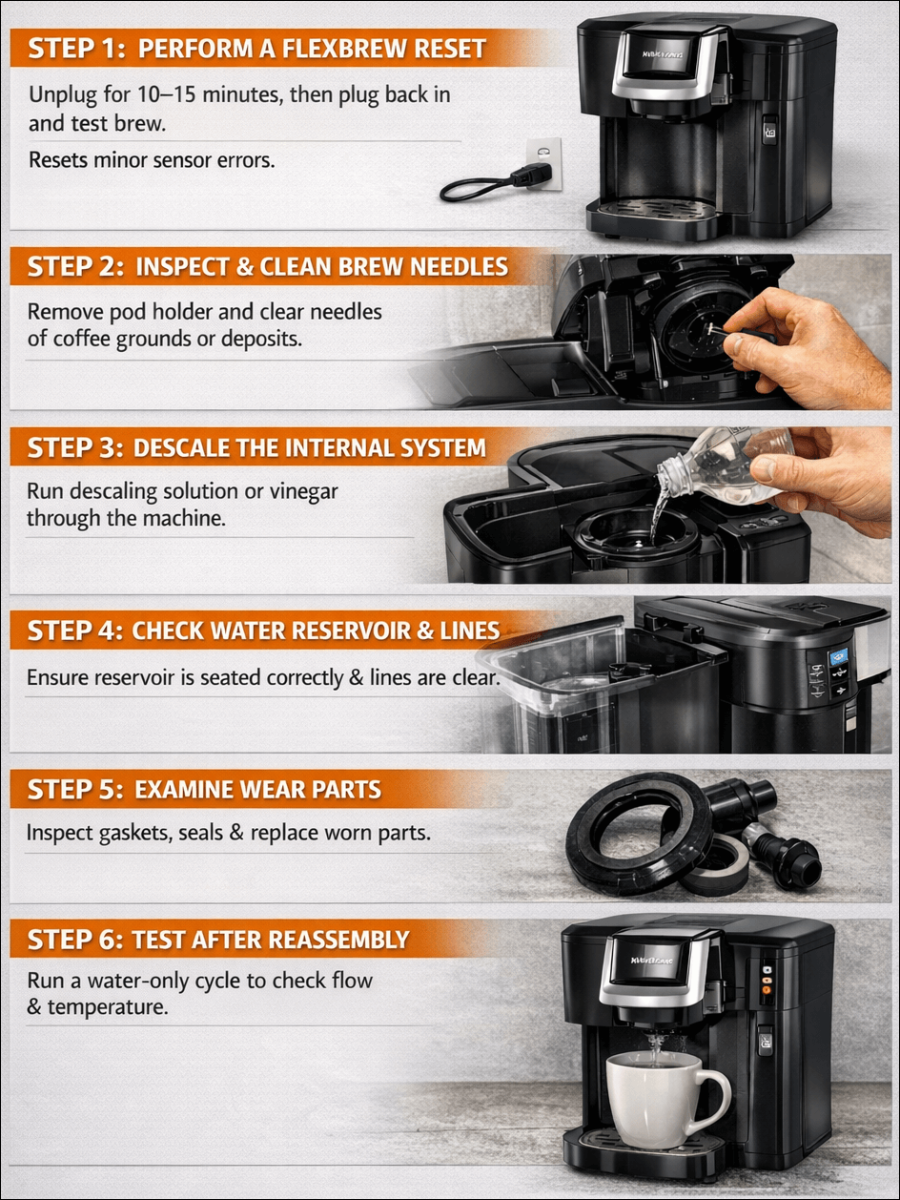

Step-by-Step Hamilton Beach FlexBrew Troubleshooting Like a Pro

Professional-level Hamilton Beach coffee maker FlexBrew troubleshooting follows a logical sequence. Always disconnect power before servicing.

|

Disclaimer: The troubleshooting and maintenance information provided in this guide and infographic is intended for general reference only. Procedures may vary by model, usage conditions, and installation environment. Always refer to the manufacturer’s service manual before performing repairs. |

Check out commercial coffee machine parts problems & how to fix them, which outlines common component issues, their causes, practical troubleshooting steps, and effective solutions to restore performance and ensure consistent operation.

Preventive Maintenance Tips to Keep Your FlexBrew Running Smoothly

Preventive maintenance is essential for minimizing Hamilton Beach FlexBrew issues, maintaining consistent brew quality, and extending the overall lifespan of the machine in commercial environments. Because FlexBrew units often operate continuously in offices, hotels, cafés, and foodservice locations, a structured maintenance routine helps prevent unexpected failures and costly downtime.

Daily Maintenance: Daily cleaning prevents debris and residue from accumulating in high-contact areas that directly affect brewing performance.

-

Empty and rinse drip trays to prevent overflow, odors, and bacterial buildup

-

Wipe brew baskets and pod holders to remove coffee oils and grounds

-

Inspect visible areas for debris or leaks that may indicate early component wear

Weekly Maintenance: Weekly maintenance targets components that experience repeated exposure to heat, pressure, and moisture.

-

Clean brew needles and brew heads to prevent clogging and water flow restrictions

-

Wash removable components using warm water and a mild detergent to remove coffee residue

-

Check seals and gaskets for early signs of wear or cracking

Monthly Maintenance: Monthly maintenance focuses on internal system health and long-term performance stability.

-

Perform a full descaling cycle to remove mineral deposits, especially in hard water regions

-

Inspect internal hoses and seals for stiffness, scaling, or leaks that may affect pressure

-

Test water flow and heating consistency to catch performance decline early

Quarterly Maintenance: Quarterly inspections help prevent major breakdowns by addressing wear before failure occurs.

-

Replace high-wear Hamilton Beach FlexBrew parts, such as valves, seals, and brew components

-

Test brew temperature accuracy and cycle timing to ensure proper extraction

-

Review maintenance logs to identify recurring issues or patterns

Using filtered water significantly reduces mineral scale buildup, minimizing Hamilton Beach FlexBrew clogged conditions and preventing frequent blinking error lights. Keeping essential Hamilton Beach FlexBrew coffee maker parts in stock ensures fast repairs and uninterrupted operation, helping commercial operators maintain consistent performance and reliability year-round.

Summary: Keep Your Hamilton Beach FlexBrew Performing at Peak Efficiency

Maintaining peak performance from a Hamilton Beach FlexBrew requires consistent care, structured maintenance, and timely part replacement. Although often overlooked compared to larger commercial appliances, coffee systems play a critical role in daily operations and demand the same level of attention. Proper maintenance ensures consistent beverage quality, reliable operation, and fewer unexpected service disruptions.

Key Takeaways:

-

Regular cleaning and descaling help prevent common Hamilton Beach FlexBrew issues and maintain stable brewing performance.

-

Following a structured Hamilton Beach coffee maker FlexBrew troubleshooting process allows early detection of operational problems.

-

Replacing worn components with genuine Hamilton Beach FlexBrew coffee maker replacement parts improves reliability and compatibility.

-

Proactive inspections reduce emergency repairs, extend equipment lifespan, and lower long-term operating costs.

-

A preventive maintenance approach keeps your FlexBrew efficient, dependable, and ready for continuous commercial use.

FAQs

How do I reset my Hamilton Beach FlexBrew?

Unplug the machine for 10–15 minutes, then reconnect power to complete a proper Hamilton Beach FlexBrew reset.

Why is my Hamilton FlexBrew not brewing?

The most common causes include scale buildup, clogged needles, sensor errors, or worn Hamilton Beach FlexBrew parts.

How to unclog a Hamilton Beach coffee maker?

Descale the system, clean brew needles, and flush water lines to resolve Hamilton Beach FlexBrew clogged conditions.

Why is my Hamilton Beach FlexBrew light blinking?

A Hamilton Beach FlexBrew light blinking usually indicates overheating, incomplete brew cycles, or maintenance-related errors.